Product Description

Product Parameters

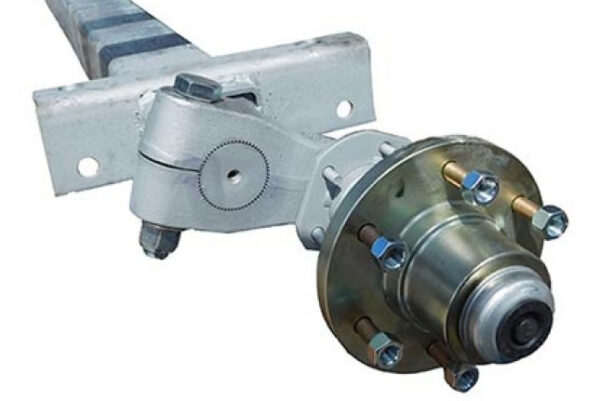

| Germany Type Bogie Suspension | ||||||||||||

| Rated Load (kg) | Weight (kg) | Bearing Type | Axle Beam | Brake Size | Track Length A | Tyre Bolt | Steel Turn Position | Wheel Base B | C mm | D mm | E mm | F mm |

| 24000 | 2571 | 33118 33213 | SQUARE 150*14 | 420*180 | 1870mm | 10-M22*1.5 | 280 | 1385 | 900 | 600 | 700 | 55 |

| 24000 | 2080 | 33118 33213 | SQUARE 150*14 | 420*200 | 1870mm | 10-M22*1.5 | 280 | 1385 | 900 | 600 | 700 | 55 |

| 28000 | 2455 | 33215 32219 | SQUARE 150*14 | 420*200 | 1870mm | 10-M22*1.5 | 280 | 1550 | 900 | 600 | 800 | 55 |

| 32000 | 2520 | 32314 32222 | SQUARE 150*16 | 420*200 | 1870mm | 10-M22*1.5 | 280 | 1550 | 900 | 600 | 800 | 55 |

| 36000 | 2600 | 32314 32222 | SQUARE 150*18 | 420*220 | 1870mm | 10-M22*1.5 | 280 | 1550 | 900 | 600 | 800 | 55 |

Product Description

Characteristics:

1. Special heat-treat, low-alloy steel axle beam, it has the vitues of good synthetic performance, strong load ability and lower self weight.

2. High quality alloy CHINAMFG inserted spindle, through wholy heat treatment, provide superior fatigue capability.

3. High performance premium non-asbestos brake linings, estend serbice life.

4. Easy for ABS installation.

5. Camshaft, matching with special seals, can ensure no entry of the grease into the brake drum, more safety.

6. New tight fit hub cap habe O rings, high property for sealing.

7. Grease lubricant is supplied by Mobil that lengthens the time of free maintenance.

8. Full range of stud fixing such as ISO, BSF and JAP, it can meet the requirements of various wheel rims.

Company Profile

Exhibition

Certifications

Scope of our business

1. Axles (German type axle, English type axle, American type axle, Spoke axle, ZM axle, Agriculture axle, Half axle, Axle without brake)

2. Suspension (Bogie suspension, One point suspension, Rigid suspension, Spoke suspension, Machinery suspension)

3. Landing gear

4. Fifth wheel (2” 3.5”)

5. King pin (2” 3.5”)

6. Semi trailer

7. Other axles and related parts (Low bed axle, hub, rims, spring, drum…)

FAQ

Q1:Are you a factory?

A:Yes,we are a factory,but not just a factory,as we have sales team,our own offices,and they

all can help the buyers and cooperative partners to decide which products are the best choices

for them,and all your requirements and inquires will be replyed in time.

Q2:What’s your Delivery Time?

A:In general, the delivery time is 15-20 days.We will make the delivery as soon as possible with

the guaranted quality.

Q3:What is the convenient way to pay?

A:L/C , T/T,Unionpay,DP are accepted,and if you have a better idea , please be free sharing with us.

Q4:Which type of shipping would be better?

A:Generally,in consideration of the cheap and safe superiorities of sea transportation,we advice

to make delivery by sea.What’s more, we respect your views of other transportation as well.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 1year |

|---|---|

| Condition: | New |

| Axle Number: | 1 |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does the choice of materials impact the durability and reliability of trailer suspensions?

The choice of materials significantly impacts the durability and reliability of trailer suspensions. Here’s a detailed explanation:

The materials used in the construction of trailer suspensions play a crucial role in determining their strength, longevity, and ability to withstand various loads and environmental conditions. Different components of the suspension system, such as springs, axles, shackles, and hangers, can be made from different materials. Here are some key factors related to materials and their impact on suspension durability and reliability:

- Strength and Load Capacity:

- Corrosion Resistance:

- Fatigue Resistance:

- Weight Reduction:

- Cost Considerations:

The materials used in suspension components need to possess sufficient strength and load-carrying capacity to handle the anticipated loads. High-strength materials, such as alloy steels or specialized composites, are often used to ensure that the suspension can withstand the weight of the trailer and its cargo. By selecting materials with appropriate strength characteristics, the suspension can maintain its structural integrity and prevent failures under heavy loads.

Trailer suspensions are exposed to various environmental conditions, including moisture, road salts, and other corrosive substances. Choosing materials with good corrosion resistance helps protect the suspension components from rust and degradation. Stainless steel, galvanized steel, or specialized coatings can be used to enhance the corrosion resistance of critical suspension parts, ensuring long-term reliability and reducing maintenance requirements.

Trailer suspensions are subjected to repeated cycles of loading and unloading as the trailer travels over uneven road surfaces. Materials with high fatigue resistance are crucial to prevent the development of cracks or fractures over time. Specialized alloys or heat treatment processes can be employed to enhance the fatigue resistance of suspension components, ensuring their long-term durability and reliability.

The choice of lightweight materials can contribute to improved fuel efficiency and payload capacity. By utilizing lightweight materials, such as aluminum alloys or advanced composites, the overall weight of the suspension system can be reduced without compromising strength and performance. This allows for increased payload capacity or improved fuel economy, depending on the specific trailer application.

The choice of materials can also impact the cost of manufacturing and maintaining trailer suspensions. Some materials may be more expensive than others, and the overall cost-effectiveness of the suspension system needs to be evaluated. It’s important to strike a balance between the desired performance, durability, and budgetary constraints.

Manufacturers of trailer suspensions carefully consider these factors when selecting materials for their products. They aim to provide suspensions that offer a balance of strength, durability, corrosion resistance, and cost-effectiveness.

In summary, the choice of materials has a significant impact on the durability and reliability of trailer suspensions. The selection of materials with appropriate strength, corrosion resistance, fatigue resistance, and weight reduction properties enhances the performance and longevity of the suspension system. By considering these factors, trailer owners can ensure that their suspensions are capable of withstanding the demands of their specific applications and operating environments.

How do trailer suspensions contribute to the adaptability and versatility of trailers in various settings?

Trailer suspensions play a pivotal role in enhancing the adaptability and versatility of trailers across different settings and applications. They provide several key benefits that contribute to the overall performance and functionality of trailers:

- 1. Load Handling: Trailer suspensions are designed to support and distribute the weight of various types of cargo. Whether it’s heavy construction materials, fragile goods, or specialized equipment, the suspension system ensures that the trailer can handle the load effectively without compromising stability.

- 2. Terrain Adaptability: Trailer suspensions are engineered to adapt to different terrains, including rough roads, off-road trails, and uneven surfaces. This adaptability allows trailers to navigate challenging environments, making them suitable for construction sites, agricultural fields, and remote areas.

- 3. Smoother Ride: A well-designed suspension system contributes to a smoother and more comfortable ride for both the trailer and its cargo. This is essential for transporting delicate or sensitive goods, as it reduces the risk of damage and ensures a better overall experience for the driver.

- 4. Stability and Control: Suspensions improve the stability and control of trailers, especially when making turns, navigating corners, or driving at high speeds. This enhances safety on the road and minimizes the risk of accidents or rollovers.

- 5. Versatile Attachment Points: Many trailer suspensions feature versatile attachment points that allow for various configurations and types of trailers. This adaptability means that a single suspension system can be used for different trailer designs, providing cost-effective solutions.

- 6. Load Distribution: Trailer suspensions distribute the weight evenly across multiple axles. This even weight distribution prevents excessive strain on individual components and tires, reducing wear and extending the lifespan of the trailer.

- 7. Adjustable Features: Some suspensions come with adjustable features such as airbags or adjustable shock absorbers. These features allow operators to fine-tune the suspension’s performance based on the specific needs of the load and terrain, further enhancing adaptability.

- 8. Maintenance Ease: Properly maintained suspensions are easier to service and repair, making trailers more adaptable in situations where maintenance or repairs are required in remote or challenging locations.

In summary, trailer suspensions are integral to the adaptability and versatility of trailers in various settings. They enable trailers to handle different loads, terrains, and conditions while ensuring safety, stability, and a smoother ride. By selecting the right suspension system and maintaining it effectively, trailer operators can optimize their trailers for a wide range of applications and environments.

How does the design of a trailer suspension impact the overall stability and comfort during towing?

The design of a trailer suspension has a significant impact on the overall stability and comfort during towing. Here’s a detailed explanation:

- Stability:

- 1. Weight Distribution: A well-designed suspension system ensures proper weight distribution across the trailer’s axles. It helps distribute the load evenly, preventing excessive weight on one axle and reducing the risk of overloading. Proper weight distribution enhances stability by maintaining the trailer’s balance and reducing the likelihood of swaying or fishtailing.

- 2. Center of Gravity: The suspension design plays a crucial role in managing the trailer’s center of gravity. A lower center of gravity improves stability by reducing the trailer’s tendency to tip or sway. Suspension systems with lower mounting points or those that incorporate features like torsion axles or independent suspension help lower the center of gravity and enhance overall stability.

- 3. Suspension Geometry: The geometry of the suspension system impacts stability by influencing factors such as wheel alignment, tracking, and roll resistance. A well-designed suspension geometry ensures that the wheels track properly, minimizing sideways movement and improving stability during turns or lane changes.

- 4. Damping Capability: The suspension design affects the damping capability, which refers to the system’s ability to absorb and dissipate shocks. Effective shock absorption reduces the transfer of vertical forces to the trailer, minimizing bouncing, oscillation, and excessive vertical movement. This helps maintain stability by preventing the trailer from becoming unsettled on uneven roads or encountering destabilizing forces.

- Comfort:

- 1. Shock Absorption: A well-designed suspension system effectively absorbs shocks and vibrations caused by road irregularities, bumps, or potholes. It utilizes components such as springs and shock absorbers to cushion the trailer, providing a smoother and more comfortable ride. Effective shock absorption reduces the jolts and vibrations felt inside the towing vehicle and minimizes the transfer of these forces to the cargo being transported.

- 2. Ride Quality: The suspension design influences the overall ride quality of the trailer. A suspension system that balances load support and shock absorption provides a more comfortable towing experience. It reduces excessive bouncing, pitching, or swaying, enhancing comfort for both the driver and passengers in the towing vehicle.

- 3. Noise and Vibration: A well-designed suspension system helps minimize noise and vibration during towing. It reduces the transmission of road-induced vibrations and impacts to the trailer’s frame and components. This results in a quieter and smoother ride, enhancing overall comfort and reducing driver fatigue.

- 4. Trailer Sway: The design of the suspension system can impact the trailer’s susceptibility to sway. Suspension systems that incorporate features like sway control mechanisms, independent suspension, or torsion axles offer improved resistance against trailer sway, enhancing stability and comfort during towing.

The design of the trailer suspension directly affects the stability of the trailer during towing:

The design of the trailer suspension also impacts the comfort experienced during towing:

In summary, the design of a trailer suspension significantly influences the overall stability and comfort during towing. A well-designed suspension system ensures proper weight distribution, manages the center of gravity, optimizes suspension geometry, and provides effective shock absorption. It enhances stability by reducing swaying, improving tracking, and minimizing vertical movement. Additionally, it improves comfort by absorbing shocks, reducing noise and vibration, and minimizing trailer sway. Choosing a suitable suspension design that meets the specific towing requirements is essential for achieving a stable and comfortable towing experience.

editor by CX 2024-01-16