Product Description

Product Description

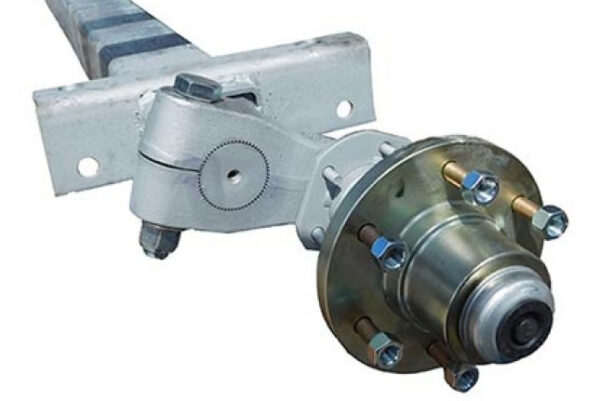

| Name | Single Point Suspension for Heavy Duty Trailers |

| Track | 1840mm/1850mm |

| Material | Steel |

| Features | Competitive Price with High Quality, OEM-DIY |

| MOQ | 1 |

| Certification | CCC, ISO |

| Brand | KHangZhou |

| Warranty | 6 month |

| OEM | Accepted |

1. Simple structure and installation between single point suspension and trailer, low manufacturing cost and easy maintenance.

2. Left and right wheels will wrap together when bouncing, with little change in tire angle, resulting in less .

3. It is not easy to change the wheel angle when the body height is lowered, so as to maintain a consistent sense of control.

4. Occupies less space and reduces the height of the floor of the ca.

Detailed Photos

1.Simplicity of design

ingle point suspension acts directly on the car body, simple installation, low manufacturing and maintenance costs.

2.Linkage Design

Left and right wheels wrap together over bumps, resulting in less tire wear.

3.High load carrying capacity

The stress point is directly shared in the axle, the pressure is directly applied to the ground, and the load bearing capacity is larger.

5.Made of high strength material

Wear-resistant and corrosion-resistant, prolonging the service life.

Product Parameters

|

model |

Rated load(T) |

weight(kg) |

Shaft tube(mm) |

Brake pads(mm) |

Track width |

Leaf spring spacing |

Recommended rims |

|

JZ2901 |

24 |

2140 |

150*150 |

420*200 |

1840mm |

980 |

7.5V-20 |

|

JZ2902 |

28 |

2540 |

150*150 |

420*200 |

1840mm |

900 |

7.5V-20 |

|

JZ2903 |

32 |

2600 |

150*150 |

420*200 |

1840mm |

900 |

8.0V-20 |

Noted1. Single point suspension can be customized according to customer’s requirements

2. Axle can be installed with optional required assembly

3. Axles can be fitted with ABS brakes.

If you have any questions, you can chat with me.

Certifications

Packaging & Shipping

Company Profile

Xihu (West Lake) Dis. KHangZhou Machinery Manufacturing Co, Ltd is located in ZheJiang Province, which is Chinese trailer production base. We are the favotry professional design and manufacture the semi-trailer parts

Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of”quality first,customer first and credit-based “since the establishment of the company and always do our best to satisfy potential needs of our customers.

Our company is sincerely willing to cooperate with enterprises from all over the world in order to realize a CHINAMFG situation since the trend of economic globalization has developed with anirresistible force.

Our Advantages

FAQ

Q1. What is your terms of packing?

A: Generally, we will package it with fumigation-free wooden holder in brown boxes. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages

before you pay the balance.

Q3. What is your terms of delivery?

A: FOB, CIF, DDU, EXW, DAP.

Q4. How about your delivery time?

A: Generally, it will take 5 to 10 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 24 Hours Online |

|---|---|

| Warranty: | 24 Hours Online |

| Type: | Suspension |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Please answer in detail: What maintenance practices are recommended for trailer suspensions to ensure optimal functionality?

Proper maintenance of trailer suspensions is crucial to ensure optimal functionality, enhance safety, and extend the lifespan of components. Here are recommended maintenance practices for trailer suspensions:

- 1. Regular Inspections: Conduct routine visual inspections of the entire suspension system, including springs, hangers, bushings, and mounting hardware. Look for signs of wear, corrosion, or damage. Inspect for loose or missing components and address any issues promptly.

- 2. Lubrication: Ensure that all moving parts, such as bushings and pivot points, are adequately lubricated. Lubrication reduces friction, minimizes wear, and promotes smooth movement. Follow the manufacturer’s recommendations for the type and frequency of lubrication.

- 3. Check Spring Alignment: Verify that leaf springs are correctly aligned and not showing signs of misalignment. Misaligned springs can lead to uneven tire wear and affect the stability of the trailer. Correct any misalignments as needed.

- 4. Inspect Shocks and Dampers: Check shock absorbers or dampers for leaks, visible damage, or signs of reduced effectiveness. Worn or damaged shocks can compromise ride quality and handling. Replace shocks that show signs of wear or failure.

- 5. Monitor Air Suspension Systems: If the trailer is equipped with air suspension, regularly inspect airbags, valves, and associated components. Check for leaks, proper inflation, and ensure that air suspension components are in good working condition. Address any air leaks promptly.

- 6. Torque Check for Fasteners: Periodically check and torque all fasteners, including bolts, nuts, and U-bolts. Loose or improperly tightened fasteners can lead to component failure and compromise the integrity of the suspension system.

- 7. Check Suspension Alignment: Verify that the suspension components are properly aligned. Misaligned components can cause uneven tire wear and affect the handling of the trailer. Correct any alignment issues to ensure even weight distribution.

- 8. Inspect Bushings and Wear Points: Check for wear on bushings and other wear points in the suspension system. Excessive wear can lead to play in the components and affect the trailer’s stability. Replace worn bushings and components as part of routine maintenance.

- 9. Examine Brake Components: Inspect brake components, including drums, pads, and calipers. Ensure that the brakes are functioning correctly and that there is even wear on the brake components. Replace any worn or damaged brake parts promptly.

- 10. Perform Wheel Alignment: Maintain proper wheel alignment to prevent irregular tire wear and ensure straight-line stability. Misaligned wheels can place additional stress on suspension components and lead to premature wear.

- 11. Address Unusual Noises: Pay attention to any unusual noises coming from the suspension during operation. Clunks, squeaks, or rattles may indicate underlying issues. Investigate and address the source of unusual noises promptly.

- 12. Follow Manufacturer Recommendations: Adhere to the manufacturer’s recommended maintenance schedule and guidelines. Manufacturers provide specific instructions for maintaining their suspension systems, and following these recommendations is essential for optimal performance and warranty compliance.

- 13. Consider Professional Inspections: Periodically, consider having the trailer suspension system professionally inspected. Trained technicians can identify potential issues that may not be visible during routine inspections, ensuring comprehensive maintenance.

By incorporating these maintenance practices into a routine schedule, trailer owners and operators can help ensure that the suspension system operates optimally, promoting safety, reliability, and longevity.

What are the signs that indicate a need for trailer suspension replacement or maintenance, and how can they be diagnosed?

Recognizing signs of trailer suspension issues is crucial for timely replacement or maintenance to ensure safe and efficient towing operations. Here are common signs and how to diagnose them:

- 1. Uneven Tire Wear: Uneven tire wear, such as cupping or feathering, can indicate suspension problems. Inspect the tires for unusual wear patterns, and if you notice uneven wear, it may suggest misalignment or worn suspension components.

- 2. Excessive Bouncing: If the trailer bounces excessively while in motion, it may be a sign of worn-out shock absorbers or dampers. You can diagnose this by observing the trailer’s behavior while driving on a smooth road. If it continues to bounce after encountering bumps, the shocks may need replacement.

- 3. Squeaking or Clunking Noises: Unusual noises, such as squeaks or clunks, coming from the suspension while driving can indicate worn or damaged components. You can diagnose this by having someone bounce the trailer while you listen for noises, or by performing a visual inspection for loose or damaged parts.

- 4. Poor Handling and Steering: Difficulty in handling or steering the trailer, especially during turns, can be a sign of suspension problems. Uneven handling or drifting may indicate suspension misalignment or worn-out components. Test the trailer’s handling by driving on a straight road and checking for any deviations.

- 5. Excessive Trailer Sway: If the trailer sways excessively from side to side, it may indicate suspension issues. This can be dangerous and is often a result of imbalanced weight distribution or worn-out suspension components. Diagnosis involves inspecting the suspension for damage and ensuring proper load distribution.

- 6. Fluid Leaks: Fluid leaks from shock absorbers or dampers are a clear sign of component failure. Inspect the shocks for visible leaks, which can often be diagnosed by oil residue or wetness around the shock body.

- 7. Sagging Suspension: A visibly sagging or lower-than-normal suspension can indicate weakened springs or overloaded suspension components. A visual inspection can quickly reveal if the suspension is not maintaining its proper ride height.

- 8. Excessive Play: When manually rocking or pushing the trailer, excessive play or movement in suspension components, such as bushings or pivot points, can suggest wear or damage. Hands-on inspection can help identify these issues.

Diagnosing trailer suspension problems typically involves a combination of visual inspection, listening for unusual noises, and observing the trailer’s behavior while driving. Regular maintenance and inspections can help detect issues early and prevent more extensive damage or accidents.

If you encounter any of these signs, it’s advisable to have the trailer suspension inspected by a qualified mechanic or technician who can provide a thorough diagnosis and recommend necessary maintenance or replacement.

Can you describe the factors to consider when selecting trailer suspensions for specific applications?

When selecting trailer suspensions for specific applications, several factors need to be considered. Here’s a detailed explanation:

- Load Capacity:

- Towing Conditions:

- Trailer Type:

- Comfort:

- Budget:

- Maintenance and Durability:

- Special Requirements:

The load capacity of the trailer suspension is a crucial factor to consider. It should be able to handle the anticipated weight of the trailer’s cargo. The suspension system should have sufficient load-carrying capacity to support the payload and distribute the weight evenly across the axles.

The towing conditions play a significant role in determining the appropriate trailer suspension. Consider factors such as the type of terrain, road conditions, and towing speed. For example, if the trailer will be frequently used on rough or uneven roads, a suspension system with excellent shock absorption capabilities, such as an independent suspension or air suspension, may be preferred.

The type of trailer being used is an essential consideration. Different trailers have varying requirements based on their intended purpose. For instance, utility trailers carrying heavy equipment may benefit from leaf spring suspensions due to their load-carrying capacity, while enclosed trailers transporting delicate cargo may require suspensions that provide superior shock absorption and stability.

If towing comfort is a priority, the suspension system’s ability to provide a smooth and stable ride becomes crucial. Factors such as shock absorption, vibration dampening, and reduced trailer sway contribute to a comfortable towing experience. Suspensions like torsion axle suspensions or air suspensions are often chosen for their superior ride quality.

The budget available for the trailer suspension is an important factor to consider. Different suspension systems have varying costs associated with their design, construction, and components. It’s important to balance the desired features and performance with the available budget.

The maintenance requirements and durability of the suspension system should be evaluated. Some suspensions may require more frequent maintenance, such as lubrication or component replacements, while others may offer longer service intervals. It’s important to consider the expected lifespan of the suspension and the associated maintenance costs.

Specific applications may have unique requirements that need to be taken into account. For example, trailers used for hauling livestock may require suspensions that minimize stress and vibrations to ensure the well-being of the animals. Specialized trailers, such as boat trailers, may need suspensions that offer protection against water or corrosion.

In summary, when selecting trailer suspensions for specific applications, factors such as load capacity, towing conditions, trailer type, comfort, budget, maintenance, durability, and any special requirements should be carefully considered. Evaluating these factors will help determine the most suitable suspension system that can provide optimal performance, stability, and comfort for the intended application.

editor by Dream 2024-04-24