Product Description

|

Vehicle specification |

||||

|

Vehicle Outline (box size) |

||||

|

Length |

14000(13900)mm |

|||

|

Width |

2550(2450)mm |

|||

|

Height |

4000(2700)mm |

|||

|

Stringer specification |

||||

|

Height |

400mm (low temperature resistance 700K2) |

|||

|

Upper CHINAMFG plate |

8mm/140mm |

|||

|

Lower CHINAMFG plate |

10mm/140mm |

|||

|

Ventral plate |

6# |

|||

|

Vehicle specification |

||||

|

Common name |

Bent parts 4# Punching |

|||

|

Second layer |

bent part |

|||

|

Side girder |

Outer G-type 3.0# for bent parts |

|||

|

Column |

Front and rear bending parts |

|||

|

Base plate |

Bamboo glue board-28# thick After installation, apply seam sealer. |

|||

|

Front gear |

Back gears to be live, laminate for front gears |

|||

|

Tool box |

1pc 1.5m long 0.6m wide 0.5m high Aluminium alloy for axle rear end |

|||

|

Spare tire rack |

1 galvanised |

|||

|

Air storage cylinder |

2 x 50 litre cylinders Aluminium alloy |

|||

|

ABS |

CHINAMFG warning light fitted |

|||

|

Lamps |

Pull-out warning light at rear end |

|||

|

Protective mesh |

Aluminium alloy |

|||

|

Traction Pins |

JOST 50# Live Pins |

|||

|

Outriggers |

ZheJiang CHINAMFG axle 28T external outrigger linkage Round foot |

|||

|

Synchronised Valves |

Imported CHINAMFG |

|||

|

Airbags |

6 airbags, full lift, front axle lift (WABCO) |

|||

|

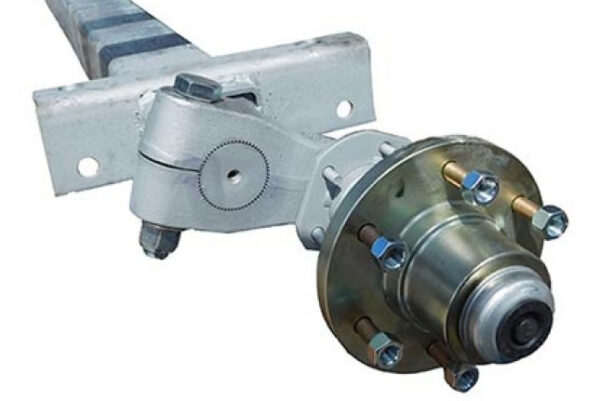

Axle |

1840 triple axle 13T disc brake (Shenli) |

|||

|

Tyres |

Triangle 385/65R22.5 (7 sets) |

|||

|

Steel rings |

Factory 11.75 (7pieces) |

|||

|

Suspension |

Air suspension |

|||

|

Brake air chambers |

Dual air chambers 6 pcs. |

|||

|

Power Supply |

24V 7-hole socket |

|||

|

Bumper |

Rear bumper made of through |

|||

|

Mudflaps |

Plastic fenders straight |

|||

|

Color |

To be determined |

|||

Product advantages

1.Side member of upper camber structure:As per the mechanical analysis,the unique overall camber structure of the longitudinal beam is adopted to ensure lifetime downward bending-free of crossbeams and effective save fuel consumption under same bearing load and build maximum economic value for users.

2.Sophisticated process:The main parts of the vehicle are fabricated by advanced equipment.The longitudinal beams are welded by imported fully automatic tracking submerged arc welding machine.The wheels and axles are assembled by assembly machine and the wheelbase is guaranteed by distance measuring equipment.

3.Suspension system:The characteristic new suspension system and imported US Holland suspension system feature balanced load among various axles.The tie rod angle of system is reasonably designed to reduce the instant friction between tire and ground and the abnormal tire wear during the frequent operation.The snap rings for shafts are one of integral casting.

4.Axles:The axles choose the quality products manufactured by professional factory,featuring high bearing capacity and difficult deformation.In addition,the optional anti-lock brake system(ABS) from domestic or foreign renowned brand can effectively eliminate the side slip and drifting of vehicle due to locking of wheels in event of emergency braking and improve the driving safety of the vehicle.

5.Light of dead weight:The partial weight reduction is conducted in multiple portions on the premises of guaranteeing the structural strength.While reducing the dead weight,the bearing capacity is effectively guaranteed.

6.Low bearing surface:The optional goose neck structure of beam effectively reduces the height of bearing surface,lowers the gravity center,and improves the transport safety.

7.Xihu (West Lake) Dis.nized design:

→The limiter is added to the spin lock to ensure safer transport;

→The design of spin lock handle features beautiful and elegant and easy operate;

→The operating handle of front enclose spin lock is located within the front enclosure frame,in order to prevent the handle from scratching the accessories of main unit.

→Two positioned three-way valve is added to the brake system to improve the safety of parking brake.

8.Electric system:The electric system adopts the genuine fully sealed harness from domestic renowned brands.The lamps adopt new LED lamp,featuring high illumination intensity and light perception,high mist penetration,stale working performance and long service life.

9.Welding procedure:Frame and top-bottom welding are all compressed tightly with pneumatic-hydraulic clamping,automatic transmission and other large tools welding,effectively control welding deformation and guarantee the smoothness and technical requirements.The turnover model makes the welding strength;The electric tilting system controls the manufacture process spare part distortion.Mixes gas welding ensures the welded joint quality.

10.Painting craft:Using the baking varnish craft,primer twice,top coat twice and detection is made strictly according to the national standard for film thickness to guarantee the paint quality and brightness.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Yes |

|---|---|

| Warranty: | Yes |

| Type: | Semi-Trailer |

| Load Capacity: | 50T |

| Certification: | ECE, GCC, CE, ISO9001, DOT, CCC, ISO/TS16949, Ottc |

| Wheel Base: | 8000-9000mm |

| Customization: |

Available

|

|

|---|

Please answer in detail: What maintenance practices are recommended for trailer suspensions to ensure optimal functionality?

Proper maintenance of trailer suspensions is crucial to ensure optimal functionality, enhance safety, and extend the lifespan of components. Here are recommended maintenance practices for trailer suspensions:

- 1. Regular Inspections: Conduct routine visual inspections of the entire suspension system, including springs, hangers, bushings, and mounting hardware. Look for signs of wear, corrosion, or damage. Inspect for loose or missing components and address any issues promptly.

- 2. Lubrication: Ensure that all moving parts, such as bushings and pivot points, are adequately lubricated. Lubrication reduces friction, minimizes wear, and promotes smooth movement. Follow the manufacturer’s recommendations for the type and frequency of lubrication.

- 3. Check Spring Alignment: Verify that leaf springs are correctly aligned and not showing signs of misalignment. Misaligned springs can lead to uneven tire wear and affect the stability of the trailer. Correct any misalignments as needed.

- 4. Inspect Shocks and Dampers: Check shock absorbers or dampers for leaks, visible damage, or signs of reduced effectiveness. Worn or damaged shocks can compromise ride quality and handling. Replace shocks that show signs of wear or failure.

- 5. Monitor Air Suspension Systems: If the trailer is equipped with air suspension, regularly inspect airbags, valves, and associated components. Check for leaks, proper inflation, and ensure that air suspension components are in good working condition. Address any air leaks promptly.

- 6. Torque Check for Fasteners: Periodically check and torque all fasteners, including bolts, nuts, and U-bolts. Loose or improperly tightened fasteners can lead to component failure and compromise the integrity of the suspension system.

- 7. Check Suspension Alignment: Verify that the suspension components are properly aligned. Misaligned components can cause uneven tire wear and affect the handling of the trailer. Correct any alignment issues to ensure even weight distribution.

- 8. Inspect Bushings and Wear Points: Check for wear on bushings and other wear points in the suspension system. Excessive wear can lead to play in the components and affect the trailer’s stability. Replace worn bushings and components as part of routine maintenance.

- 9. Examine Brake Components: Inspect brake components, including drums, pads, and calipers. Ensure that the brakes are functioning correctly and that there is even wear on the brake components. Replace any worn or damaged brake parts promptly.

- 10. Perform Wheel Alignment: Maintain proper wheel alignment to prevent irregular tire wear and ensure straight-line stability. Misaligned wheels can place additional stress on suspension components and lead to premature wear.

- 11. Address Unusual Noises: Pay attention to any unusual noises coming from the suspension during operation. Clunks, squeaks, or rattles may indicate underlying issues. Investigate and address the source of unusual noises promptly.

- 12. Follow Manufacturer Recommendations: Adhere to the manufacturer’s recommended maintenance schedule and guidelines. Manufacturers provide specific instructions for maintaining their suspension systems, and following these recommendations is essential for optimal performance and warranty compliance.

- 13. Consider Professional Inspections: Periodically, consider having the trailer suspension system professionally inspected. Trained technicians can identify potential issues that may not be visible during routine inspections, ensuring comprehensive maintenance.

By incorporating these maintenance practices into a routine schedule, trailer owners and operators can help ensure that the suspension system operates optimally, promoting safety, reliability, and longevity.

How do trailer suspensions contribute to the adaptability and versatility of trailers in various settings?

Trailer suspensions play a pivotal role in enhancing the adaptability and versatility of trailers across different settings and applications. They provide several key benefits that contribute to the overall performance and functionality of trailers:

- 1. Load Handling: Trailer suspensions are designed to support and distribute the weight of various types of cargo. Whether it’s heavy construction materials, fragile goods, or specialized equipment, the suspension system ensures that the trailer can handle the load effectively without compromising stability.

- 2. Terrain Adaptability: Trailer suspensions are engineered to adapt to different terrains, including rough roads, off-road trails, and uneven surfaces. This adaptability allows trailers to navigate challenging environments, making them suitable for construction sites, agricultural fields, and remote areas.

- 3. Smoother Ride: A well-designed suspension system contributes to a smoother and more comfortable ride for both the trailer and its cargo. This is essential for transporting delicate or sensitive goods, as it reduces the risk of damage and ensures a better overall experience for the driver.

- 4. Stability and Control: Suspensions improve the stability and control of trailers, especially when making turns, navigating corners, or driving at high speeds. This enhances safety on the road and minimizes the risk of accidents or rollovers.

- 5. Versatile Attachment Points: Many trailer suspensions feature versatile attachment points that allow for various configurations and types of trailers. This adaptability means that a single suspension system can be used for different trailer designs, providing cost-effective solutions.

- 6. Load Distribution: Trailer suspensions distribute the weight evenly across multiple axles. This even weight distribution prevents excessive strain on individual components and tires, reducing wear and extending the lifespan of the trailer.

- 7. Adjustable Features: Some suspensions come with adjustable features such as airbags or adjustable shock absorbers. These features allow operators to fine-tune the suspension’s performance based on the specific needs of the load and terrain, further enhancing adaptability.

- 8. Maintenance Ease: Properly maintained suspensions are easier to service and repair, making trailers more adaptable in situations where maintenance or repairs are required in remote or challenging locations.

In summary, trailer suspensions are integral to the adaptability and versatility of trailers in various settings. They enable trailers to handle different loads, terrains, and conditions while ensuring safety, stability, and a smoother ride. By selecting the right suspension system and maintaining it effectively, trailer operators can optimize their trailers for a wide range of applications and environments.

In what types of trailers are suspensions commonly used, and how do they vary?

Suspensions are commonly used in various types of trailers to provide support, stability, and shock absorption. Here’s a detailed explanation:

- Types of Trailers:

- 1. Utility Trailers: Utility trailers, including flatbed trailers, equipment trailers, and landscape trailers, often feature suspensions. These trailers are designed to transport a wide range of materials, equipment, or goods and require suspensions to ensure load support, stability, and a smoother ride.

- 2. Enclosed Trailers: Enclosed trailers, such as cargo trailers and box trailers, are commonly equipped with suspensions. These trailers are used for transporting goods that require protection from the elements and benefit from suspensions to absorb shocks, enhance stability, and protect the cargo.

- 3. Livestock Trailers: Livestock trailers, used for transporting animals, typically have suspensions to provide a smoother ride and minimize stress on the animals. The suspensions help absorb shocks and vibrations, ensuring the well-being and safety of the livestock during transportation.

- 4. RV Trailers: Recreational vehicles (RVs), including travel trailers and fifth-wheel trailers, utilize suspensions to enhance comfort and stability. These trailers are designed for living and leisure purposes and benefit from suspensions to provide a smoother ride, reduce vibrations, and improve overall towing experience.

- 5. Boat Trailers: Boat trailers, used for transporting boats to and from the water, often feature suspensions. These suspensions help absorb road shocks and vibrations, ensuring the safety of the boat during transportation and minimizing potential damage to the hull and other components.

- Variations in Suspensions:

- 1. Leaf Spring Suspension: Leaf spring suspensions are widely used in trailers and consist of multiple layers of curved metal strips (leaves) that flex and absorb shocks. They are known for their durability, load-carrying capacity, and cost-effectiveness.

- 2. Coil Spring Suspension: Coil spring suspensions use helical coil springs to provide support and shock absorption. They offer a smoother ride and are commonly used in trailers that require improved comfort, such as RVs or enclosed trailers.

- 3. Torsion Axle Suspension: Torsion axle suspensions use a rubberized torsion arm system to provide independent suspension for each wheel. They offer excellent shock absorption, improved stability, and are commonly used in utility trailers and RVs.

- 4. Air Suspension: Air suspensions utilize airbags to support the trailer’s weight and provide adjustable suspension stiffness. They offer a high level of adjustability, enhanced ride quality, and are commonly used in heavy-duty trailers or specialized applications.

- 5. Independent Suspension: Independent suspensions allow each wheel to move independently, providing superior shock absorption and stability. They are commonly used in high-end trailers, including luxury RVs or high-performance trailers.

Suspensions are commonly found in the following types of trailers:

Suspensions used in trailers can vary based on their design, construction, and intended use. Here are some common variations:

In summary, suspensions are commonly used in utility trailers, enclosed trailers, livestock trailers, RV trailers, and boat trailers. The choice of suspension varies based on trailer type and requirements. Common variations include leaf spring suspension, coil spring suspension, torsion axle suspension, air suspension, and independent suspension. Each type offers specific benefits in terms of load support, shock absorption, stability, and ride quality, catering to the diverse needs of different trailer applications.

editor by CX 2024-03-05