Product Description

Product Description

1. Carry greater vertical load and better torque.

2. Easy installation, low price, long service life, low maintenance cost.

3. It is suitable for various road conditions and has many optional specifications.

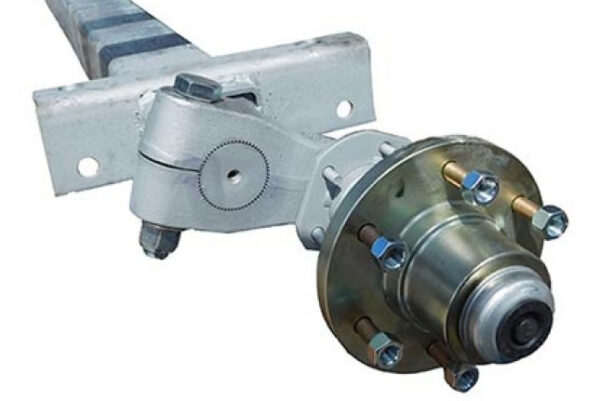

Hanger Assembly

The suspension is stamped and welded with Q345 steel plate material, which is light in weight and strong in

rigidity. The leaf spring will not shift during use.

Leaf Spring

Suspension can be matched with different width/ thickness/number of pieces, we can recommend the number

of leaf springs according to the load. Use high-quality steel, long life and large load

Ordinary semi-trailer body, axles and suspension systems, axle and suspension system located at the base of the body, among them,the axle is a barbell, on both ends of the axle set wheels, the lateral set on the bottom of the body, between the body and the axle suspension system to connect the axle and the body: when the body drag force, the body through the suspension system located at the ends of the axle wheel movement.Semi-trailer plate spring suspension (plate spring suspension for short) is divided into less plate variable cross-section steel suspension and constant cross-section multi-plate spring suspension.At present, more than 95% of the domestic heavy truck suspension system is based on the plate spring as the elastic element and guide device of the non-independent suspension, its main advantages are simple structure, easy manufacturing, convenient maintenance, mature technology, reliable work.

The trailer suspension is a device that connects the trailer frame with the axle wheel.Its main function is to transfer the various forces and moments between the wheels and the frame, and reduce and eliminate the impact load and vibration from the road surface to the frame through the axle, so as to improve the ride comfort of the trailer.

More information on mechanical suspension (for reference only)

1. Semi-trailer suspension provides 2.2 axle system, 3 axle system, 4 axle system and single point suspension system

2. The front, middle and rear spring hangers are made of high-strength low-alloy steel plates (pressure welded structure), which are stronger but lighter than the old ones

3. The new design can prevent the spring back from moving sideways during operation. The 90mm wide steel spring back is made of high-quality materials

4. Antifriction block (welding) is made of high-strength steel plate material (or # 20cast steel)

5. Its angle is consistent with the expansion direction between the steel plate spring and the rocker anti-friction block.

6. The angle of torque arm shall be adjusted scientifically. It can effectively reduce the instantaneous sliding distance between the tire and the ground, effectively reduce the friction of the tire, and increase the service life of the tire.

7. The torque arm bushing is made of polyurethane rubber. It has a cushioning function, which can cushion the instantaneous wear of the tire when sliding and shifting.

8. The above features, together with correct installation, reliably ensure the perpendicularity between the axle and the kingpin, effectively eliminate offset wear and gnawing, and make the tire wear even.

Precautions for mechanical suspension (for reference only)

1. Can be equipped with 13/16/20T

2. The graph axis/square axis can be configured.

3. You can choose to install now or reverse.

4. It may be necessary to select the side wall thickness of 6mm, 8mm or 10mm

5. Spring specification: width 90mm, 100120mm: number of leaves optional

6. A: no-load size, B: full-load size

Product Recommended

Why Choose US

HangZhou Hongruida Trailer Parts Co., Ltd. Mainly produces semi trailer and its related trailer accessories, truck parts, including various types of American type trailer axle, concave axle, spoke axle, German type trailer axle, agricultural axle, American type suspension, single point suspension, rigid suspension, air suspension, leaf spring and landing gear, kingpin, air chamber, air reservoir, etc. Our sales network covers all regions of the world. Both new and old customers support customization.

We have advanced processing technology, first-class production line, professional production quality, high-quality service concept, guarantee your trailer business brighter! Our products are produced strictly in accordance with national implementation standards, with reasonable prices, and the cost performance ratio is far ahead in the industry, which is highly praised by customers!

High quality, competitive price to continue to provide customers witih best products is our constant pursuit. With advanced first class production equipments and high technology engineerings, which make high quality and one-to-1 24 hours full-time service, our products are being exported more than 30 countries with the right to import and export. Welcome your inquiry.

Our Service

1. Advanced equipment and rich experience workers are applied during the whole producing process to ensure the quality of Low bed semi trailer.

2. We have passed ISO9001:2008, CCC, BV, SGS, TUV.

3. We have more than 20 years of experience and a strong team of engineers, we are manufacturer, we could design the product according to your special requirements.

4. We have rest assured after-sales service.

Packaging & Shipping

We usually adopt shipping by bulk cargo, flat rack, container container and Roro ship. We will arrange the most cost-effective transportation mode according to the quantity of products. All trailers will be polished with wax before shipping. We guarantee that all products have gone through strict inspection and are in good condition before shipment. We strive for 100% customer satisfaction on every sale we close.

Delivery time:10-20 working days after payment receipt confirmed (based on actual quantity).

Packing:Standard export packing, or customized packing as your request.

Professional goods shipping forwarder.

FAQ

1. How is the quality of your products?

Our products are manufactured in strict accordance with national and international standards, and we test each product before delivery. If you would like to view our quality certification and various test reports, please contact us.

2. How about price?

We are a factory and able to give you the lowest price. Please trust the quotation we would give you, and it is professional one.

3. Why should you chose us?

Choosing us happens because of quality, then price, and we can give you both. Additionally, we can also offer professional products inquiry,products knowledge train(for agents), smooth goods delivery, excellent customer solution proposals.

4. How to ensure the interests of buyers?

Our company supports Alibaba online trading, which not only ensures the safety of the buyer’s funds, but also guarantees the quality of the goods. From the outbound, to the loading, and finally to the receiving, the whole process is transparent.

5. How to guarantee delivery time?

We are a factory with a large inventory of stock, which guarantees that the goods will be shipped within the shortest time from the date of signing the contract.

6. How to get samples?

We can provide samples for buyer’s testing free of charge, but buyers need to pay for shipping costs.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 1 Year |

|---|---|

| Type: | Air Suspension |

| Certification: | ISO/TS16949, CE |

| Loading Weight: | 25T |

| ABS: | With ABS |

| Tent Type: | Simple |

| Customization: |

Available

|

|

|---|

Please answer in detail: What maintenance practices are recommended for trailer suspensions to ensure optimal functionality?

Proper maintenance of trailer suspensions is crucial to ensure optimal functionality, enhance safety, and extend the lifespan of components. Here are recommended maintenance practices for trailer suspensions:

- 1. Regular Inspections: Conduct routine visual inspections of the entire suspension system, including springs, hangers, bushings, and mounting hardware. Look for signs of wear, corrosion, or damage. Inspect for loose or missing components and address any issues promptly.

- 2. Lubrication: Ensure that all moving parts, such as bushings and pivot points, are adequately lubricated. Lubrication reduces friction, minimizes wear, and promotes smooth movement. Follow the manufacturer’s recommendations for the type and frequency of lubrication.

- 3. Check Spring Alignment: Verify that leaf springs are correctly aligned and not showing signs of misalignment. Misaligned springs can lead to uneven tire wear and affect the stability of the trailer. Correct any misalignments as needed.

- 4. Inspect Shocks and Dampers: Check shock absorbers or dampers for leaks, visible damage, or signs of reduced effectiveness. Worn or damaged shocks can compromise ride quality and handling. Replace shocks that show signs of wear or failure.

- 5. Monitor Air Suspension Systems: If the trailer is equipped with air suspension, regularly inspect airbags, valves, and associated components. Check for leaks, proper inflation, and ensure that air suspension components are in good working condition. Address any air leaks promptly.

- 6. Torque Check for Fasteners: Periodically check and torque all fasteners, including bolts, nuts, and U-bolts. Loose or improperly tightened fasteners can lead to component failure and compromise the integrity of the suspension system.

- 7. Check Suspension Alignment: Verify that the suspension components are properly aligned. Misaligned components can cause uneven tire wear and affect the handling of the trailer. Correct any alignment issues to ensure even weight distribution.

- 8. Inspect Bushings and Wear Points: Check for wear on bushings and other wear points in the suspension system. Excessive wear can lead to play in the components and affect the trailer’s stability. Replace worn bushings and components as part of routine maintenance.

- 9. Examine Brake Components: Inspect brake components, including drums, pads, and calipers. Ensure that the brakes are functioning correctly and that there is even wear on the brake components. Replace any worn or damaged brake parts promptly.

- 10. Perform Wheel Alignment: Maintain proper wheel alignment to prevent irregular tire wear and ensure straight-line stability. Misaligned wheels can place additional stress on suspension components and lead to premature wear.

- 11. Address Unusual Noises: Pay attention to any unusual noises coming from the suspension during operation. Clunks, squeaks, or rattles may indicate underlying issues. Investigate and address the source of unusual noises promptly.

- 12. Follow Manufacturer Recommendations: Adhere to the manufacturer’s recommended maintenance schedule and guidelines. Manufacturers provide specific instructions for maintaining their suspension systems, and following these recommendations is essential for optimal performance and warranty compliance.

- 13. Consider Professional Inspections: Periodically, consider having the trailer suspension system professionally inspected. Trained technicians can identify potential issues that may not be visible during routine inspections, ensuring comprehensive maintenance.

By incorporating these maintenance practices into a routine schedule, trailer owners and operators can help ensure that the suspension system operates optimally, promoting safety, reliability, and longevity.

What safety considerations should be taken into account when using trailer suspensions in towing?

When using trailer suspensions in towing, it’s crucial to prioritize safety to prevent accidents and ensure the well-being of both the driver and other road users. Here are important safety considerations to keep in mind:

- 1. Weight Distribution: Properly distribute the weight of the cargo within the trailer. Ensure that the load is evenly balanced to prevent overloading of one axle or side, which can lead to instability and loss of control.

- 2. Load Capacity: Stay within the specified load capacity of the trailer suspension. Overloading can strain the suspension components, leading to premature wear and potential failure.

- 3. Regular Inspections: Conduct routine inspections of the trailer suspension system, including springs, shocks, and fasteners. Look for signs of wear, damage, or loose components. Address any issues promptly to prevent accidents.

- 4. Tire Maintenance: Ensure that trailer tires are in good condition, properly inflated, and have adequate tread depth. Bald or underinflated tires can lead to blowouts or loss of control during towing.

- 5. Brake System: Maintain the trailer’s brake system in optimal condition. Test and adjust the brakes as needed to ensure they provide effective stopping power. Inadequate brakes can result in longer stopping distances and accidents.

- 6. Trailer Lights: Ensure that all trailer lights, including brake lights, turn signals, and taillights, are functioning correctly. Proper lighting enhances visibility and signals your intentions to other drivers.

- 7. Trailer Hitch: Use a compatible and properly installed trailer hitch that is rated for the weight of your trailer and load. Make sure the hitch is securely attached to the towing vehicle and the trailer tongue.

- 8. Secure Cargo: Secure the cargo inside the trailer to prevent shifting during transit. Use appropriate tie-downs and restraints to keep the load stable and prevent accidents caused by cargo movement.

- 9. Driving Speed: Adhere to safe driving speeds and follow posted speed limits. Speeding while towing can reduce your ability to react to unexpected situations and increase the risk of accidents.

- 10. Towing Vehicle: Ensure that the towing vehicle is in good mechanical condition. Regularly service the vehicle’s engine, brakes, transmission, and suspension to maintain towing performance and safety.

- 11. Emergency Equipment: Carry essential emergency equipment, including a jack, spare tire, fire extinguisher, first aid kit, and reflective warning triangles. These items can be invaluable in case of roadside emergencies.

- 12. Weather Conditions: Adjust your driving behavior and maintain a safe following distance in adverse weather conditions, such as rain, snow, or ice. Wet or slippery roads can increase stopping distances and reduce traction.

- 13. Driver Training: Ensure that the driver has the necessary training and experience in towing trailers. Towing a trailer requires specific skills and awareness of handling differences compared to driving without a trailer.

- 14. Emergency Procedures: Familiarize yourself with emergency procedures, including how to react in the event of trailer sway, jackknifing, or other critical situations. Knowing how to respond can prevent accidents from escalating.

Prioritizing safety when using trailer suspensions in towing is essential for preventing accidents and ensuring a secure and efficient towing experience. Regular maintenance, proper load management, and adherence to safety guidelines are key to safe towing operations.

Can you describe the factors to consider when selecting trailer suspensions for specific applications?

When selecting trailer suspensions for specific applications, several factors need to be considered. Here’s a detailed explanation:

- Load Capacity:

- Towing Conditions:

- Trailer Type:

- Comfort:

- Budget:

- Maintenance and Durability:

- Special Requirements:

The load capacity of the trailer suspension is a crucial factor to consider. It should be able to handle the anticipated weight of the trailer’s cargo. The suspension system should have sufficient load-carrying capacity to support the payload and distribute the weight evenly across the axles.

The towing conditions play a significant role in determining the appropriate trailer suspension. Consider factors such as the type of terrain, road conditions, and towing speed. For example, if the trailer will be frequently used on rough or uneven roads, a suspension system with excellent shock absorption capabilities, such as an independent suspension or air suspension, may be preferred.

The type of trailer being used is an essential consideration. Different trailers have varying requirements based on their intended purpose. For instance, utility trailers carrying heavy equipment may benefit from leaf spring suspensions due to their load-carrying capacity, while enclosed trailers transporting delicate cargo may require suspensions that provide superior shock absorption and stability.

If towing comfort is a priority, the suspension system’s ability to provide a smooth and stable ride becomes crucial. Factors such as shock absorption, vibration dampening, and reduced trailer sway contribute to a comfortable towing experience. Suspensions like torsion axle suspensions or air suspensions are often chosen for their superior ride quality.

The budget available for the trailer suspension is an important factor to consider. Different suspension systems have varying costs associated with their design, construction, and components. It’s important to balance the desired features and performance with the available budget.

The maintenance requirements and durability of the suspension system should be evaluated. Some suspensions may require more frequent maintenance, such as lubrication or component replacements, while others may offer longer service intervals. It’s important to consider the expected lifespan of the suspension and the associated maintenance costs.

Specific applications may have unique requirements that need to be taken into account. For example, trailers used for hauling livestock may require suspensions that minimize stress and vibrations to ensure the well-being of the animals. Specialized trailers, such as boat trailers, may need suspensions that offer protection against water or corrosion.

In summary, when selecting trailer suspensions for specific applications, factors such as load capacity, towing conditions, trailer type, comfort, budget, maintenance, durability, and any special requirements should be carefully considered. Evaluating these factors will help determine the most suitable suspension system that can provide optimal performance, stability, and comfort for the intended application.

editor by CX 2024-03-13