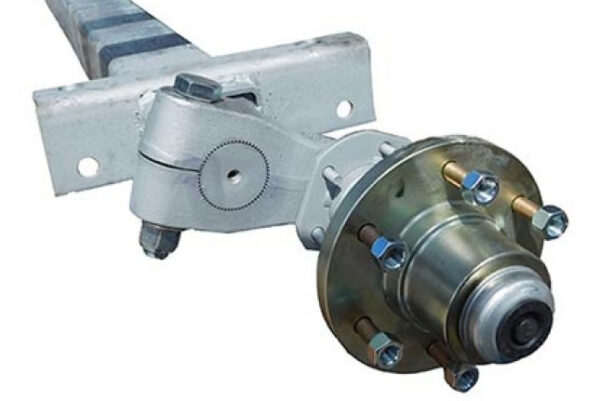

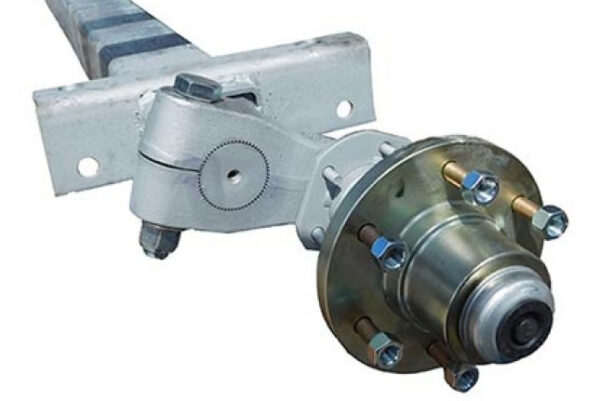

Product Description

Suspension Features:

1) Tandem, Tridem, Quad, all are available.

2) From 12tons to 20tons capacity to meet different requirements

3) Different leaf spring are available.

4) Different RH are available.

5) Strict quality control process to assure excellent quality.

6) Successful experience worldwide.

Application

Packaging &Shipping

Company Profile

Cavwo is a professional manufacturer specializing in trailer suspension parts and truck chassis parts, which is located in HangZhou, ZheJiang , China. Built in 1997, we have a 20, 000 square CHINAMFG factory, advanced production line equipment, excellent production, and a technical team. The company mainly deals with Leaf Springs, Air Springs, Xihu (West Lake) Dis. Arms, Shock Absorbers, Trailer Suspension, Axles, Brake Drums, Brake Linings, Steel Wheels, Tires, and other products. Since its establishment, the company has always focused on the research and development and operation of truck parts and components, with a variety of operating characteristics and the principle of small profits and high sales, favored by the majority of customers.

The company’s sales of trailer suspension parts and truck chassis parts have covered dozens of countries and regions in South America, North America, Europe, Asia, Africa, and Oceania.

The company advocates “make the work effective, make the staff have achievements”, focuses on staff training and development, constantly introduces advanced management concepts, optimizes and innovates the management mode, reasonably allocates resources, improves the team’s efficiency, and helps the staff to realize their self-worth.

The company will always adhere to the values of “responsibility & win-win”, not obsessed with ineffective competition, but only focus on the pursuit of quality and customer satisfaction, and take action to fulfill the commitment and contribution to society so that Cavwo becomes a respected brand in the global automotive aftermarket.

FAQ

Q1: What material of the leaf spring can you supply?

A: We can supply different materials of leaf spring, including 60Si2Mn, SUP9,50CrV, 51CrV4, or any material as you require. Before placing the order, please make sure the material to us or we can advise the material to you according to your specification.

Q2: How about the quality of your product?

A: Our products are certified to ISO9001, TS16949 international quality standards.

Q3:Could we print our own logo or label on the springs?

A: Yes, you can. We support logo print & label print & stamping.

Q4. How about your delivery time?

A: Generally, it will take 20 to 30 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Tailer Suspension |

|---|---|

| Certification: | ISO/TS16949 |

| ABS: | Without ABS |

| Color: | Customized |

| Condition: | New |

| Material: | Steel |

| Customization: |

Available

|

|

|---|

Please answer in detail: What maintenance practices are recommended for trailer suspensions to ensure optimal functionality?

Proper maintenance of trailer suspensions is crucial to ensure optimal functionality, enhance safety, and extend the lifespan of components. Here are recommended maintenance practices for trailer suspensions:

- 1. Regular Inspections: Conduct routine visual inspections of the entire suspension system, including springs, hangers, bushings, and mounting hardware. Look for signs of wear, corrosion, or damage. Inspect for loose or missing components and address any issues promptly.

- 2. Lubrication: Ensure that all moving parts, such as bushings and pivot points, are adequately lubricated. Lubrication reduces friction, minimizes wear, and promotes smooth movement. Follow the manufacturer’s recommendations for the type and frequency of lubrication.

- 3. Check Spring Alignment: Verify that leaf springs are correctly aligned and not showing signs of misalignment. Misaligned springs can lead to uneven tire wear and affect the stability of the trailer. Correct any misalignments as needed.

- 4. Inspect Shocks and Dampers: Check shock absorbers or dampers for leaks, visible damage, or signs of reduced effectiveness. Worn or damaged shocks can compromise ride quality and handling. Replace shocks that show signs of wear or failure.

- 5. Monitor Air Suspension Systems: If the trailer is equipped with air suspension, regularly inspect airbags, valves, and associated components. Check for leaks, proper inflation, and ensure that air suspension components are in good working condition. Address any air leaks promptly.

- 6. Torque Check for Fasteners: Periodically check and torque all fasteners, including bolts, nuts, and U-bolts. Loose or improperly tightened fasteners can lead to component failure and compromise the integrity of the suspension system.

- 7. Check Suspension Alignment: Verify that the suspension components are properly aligned. Misaligned components can cause uneven tire wear and affect the handling of the trailer. Correct any alignment issues to ensure even weight distribution.

- 8. Inspect Bushings and Wear Points: Check for wear on bushings and other wear points in the suspension system. Excessive wear can lead to play in the components and affect the trailer’s stability. Replace worn bushings and components as part of routine maintenance.

- 9. Examine Brake Components: Inspect brake components, including drums, pads, and calipers. Ensure that the brakes are functioning correctly and that there is even wear on the brake components. Replace any worn or damaged brake parts promptly.

- 10. Perform Wheel Alignment: Maintain proper wheel alignment to prevent irregular tire wear and ensure straight-line stability. Misaligned wheels can place additional stress on suspension components and lead to premature wear.

- 11. Address Unusual Noises: Pay attention to any unusual noises coming from the suspension during operation. Clunks, squeaks, or rattles may indicate underlying issues. Investigate and address the source of unusual noises promptly.

- 12. Follow Manufacturer Recommendations: Adhere to the manufacturer’s recommended maintenance schedule and guidelines. Manufacturers provide specific instructions for maintaining their suspension systems, and following these recommendations is essential for optimal performance and warranty compliance.

- 13. Consider Professional Inspections: Periodically, consider having the trailer suspension system professionally inspected. Trained technicians can identify potential issues that may not be visible during routine inspections, ensuring comprehensive maintenance.

By incorporating these maintenance practices into a routine schedule, trailer owners and operators can help ensure that the suspension system operates optimally, promoting safety, reliability, and longevity.

How does the choice of trailer suspensions affect the overall performance and reliability of a trailer?

The choice of trailer suspensions has a significant impact on the overall performance and reliability of a trailer. It influences various aspects of trailer operation and functionality. Here’s how:

- 1. Load Capacity: The type and design of trailer suspensions determine the trailer’s load-carrying capacity. Choosing suspensions with the appropriate load rating ensures that the trailer can safely carry the intended cargo without overloading or straining the suspension components.

- 2. Ride Quality: The choice of suspensions affects the ride quality for both the trailer and the cargo. A well-matched suspension system can provide a smoother and more stable ride, reducing the risk of cargo damage and enhancing driver comfort.

- 3. Handling and Maneuverability: Different suspension systems offer varying levels of handling and maneuverability. Some suspensions are designed for stability during high-speed highway travel, while others excel in off-road or rugged terrain. Choosing the right suspension type ensures optimal handling characteristics.

- 4. Durability and Longevity: The quality and construction of trailer suspensions play a vital role in their durability. High-quality suspensions are less prone to wear and are designed to withstand the rigors of heavy-duty use, resulting in longer service life and increased reliability.

- 5. Maintenance Requirements: The maintenance needs of trailer suspensions can vary depending on their type and design. Some suspensions require more frequent lubrication and inspection, while others are designed for minimal maintenance. Selecting suspensions that align with your maintenance capabilities can affect long-term reliability.

- 6. Adaptability to Terrain: The choice of suspensions impacts the trailer’s adaptability to different terrains. Air suspensions, for example, excel in providing a smooth ride on rough or uneven surfaces, enhancing versatility and reliability in various settings.

- 7. Safety: Properly matched suspensions contribute to trailer safety. A well-balanced suspension system helps prevent trailer sway, reduces the risk of rollovers, and enhances stability during emergency maneuvers, improving overall safety.

- 8. Fuel Efficiency: Some suspensions are designed to minimize rolling resistance, which can improve fuel efficiency. Choosing fuel-efficient suspensions can lead to cost savings over the trailer’s operational lifespan.

- 9. Compatibility with Towing Vehicle: The choice of trailer suspensions should consider the towing vehicle’s specifications. Ensuring compatibility between the trailer suspensions and the towing vehicle’s capabilities is essential for safe and reliable towing.

- 10. Load Distribution: Trailer suspensions play a critical role in distributing the weight of the cargo evenly across the axles. Proper load distribution enhances stability, prevents overloading, and reduces the risk of component wear or failure.

In summary, the choice of trailer suspensions directly impacts the trailer’s performance, reliability, and safety. It’s essential to carefully consider factors such as load capacity, terrain, maintenance requirements, and intended use when selecting suspensions to ensure that they align with the specific needs of your trailer and operational requirements.

How does the design of a trailer suspension impact the overall stability and comfort during towing?

The design of a trailer suspension has a significant impact on the overall stability and comfort during towing. Here’s a detailed explanation:

- Stability:

- 1. Weight Distribution: A well-designed suspension system ensures proper weight distribution across the trailer’s axles. It helps distribute the load evenly, preventing excessive weight on one axle and reducing the risk of overloading. Proper weight distribution enhances stability by maintaining the trailer’s balance and reducing the likelihood of swaying or fishtailing.

- 2. Center of Gravity: The suspension design plays a crucial role in managing the trailer’s center of gravity. A lower center of gravity improves stability by reducing the trailer’s tendency to tip or sway. Suspension systems with lower mounting points or those that incorporate features like torsion axles or independent suspension help lower the center of gravity and enhance overall stability.

- 3. Suspension Geometry: The geometry of the suspension system impacts stability by influencing factors such as wheel alignment, tracking, and roll resistance. A well-designed suspension geometry ensures that the wheels track properly, minimizing sideways movement and improving stability during turns or lane changes.

- 4. Damping Capability: The suspension design affects the damping capability, which refers to the system’s ability to absorb and dissipate shocks. Effective shock absorption reduces the transfer of vertical forces to the trailer, minimizing bouncing, oscillation, and excessive vertical movement. This helps maintain stability by preventing the trailer from becoming unsettled on uneven roads or encountering destabilizing forces.

- Comfort:

- 1. Shock Absorption: A well-designed suspension system effectively absorbs shocks and vibrations caused by road irregularities, bumps, or potholes. It utilizes components such as springs and shock absorbers to cushion the trailer, providing a smoother and more comfortable ride. Effective shock absorption reduces the jolts and vibrations felt inside the towing vehicle and minimizes the transfer of these forces to the cargo being transported.

- 2. Ride Quality: The suspension design influences the overall ride quality of the trailer. A suspension system that balances load support and shock absorption provides a more comfortable towing experience. It reduces excessive bouncing, pitching, or swaying, enhancing comfort for both the driver and passengers in the towing vehicle.

- 3. Noise and Vibration: A well-designed suspension system helps minimize noise and vibration during towing. It reduces the transmission of road-induced vibrations and impacts to the trailer’s frame and components. This results in a quieter and smoother ride, enhancing overall comfort and reducing driver fatigue.

- 4. Trailer Sway: The design of the suspension system can impact the trailer’s susceptibility to sway. Suspension systems that incorporate features like sway control mechanisms, independent suspension, or torsion axles offer improved resistance against trailer sway, enhancing stability and comfort during towing.

The design of the trailer suspension directly affects the stability of the trailer during towing:

The design of the trailer suspension also impacts the comfort experienced during towing:

In summary, the design of a trailer suspension significantly influences the overall stability and comfort during towing. A well-designed suspension system ensures proper weight distribution, manages the center of gravity, optimizes suspension geometry, and provides effective shock absorption. It enhances stability by reducing swaying, improving tracking, and minimizing vertical movement. Additionally, it improves comfort by absorbing shocks, reducing noise and vibration, and minimizing trailer sway. Choosing a suitable suspension design that meets the specific towing requirements is essential for achieving a stable and comfortable towing experience.

editor by Dream 2024-04-23