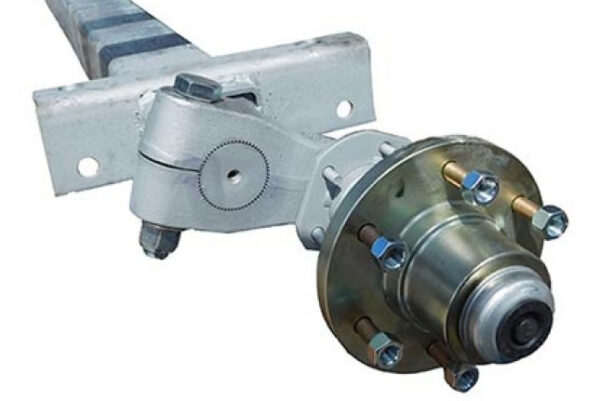

Product Description

Suspension Features:

1) Tandem, Tridem, Quad, all are available.

2) From 12tons to 20tons capacity to meet different requirements

3) Different leaf spring are available.

4) Different RH are available.

5) Strict quality control process to assure excellent quality.

6) Successful experience worldwide.

Application

Packaging &Shipping

Company Profile

Cavwo is a professional manufacturer specializing in trailer suspension parts and truck chassis parts, which is located in HangZhou, ZheJiang , China. Built in 1997, we have a 20, 000 square CHINAMFG factory, advanced production line equipment, excellent production, and a technical team. The company mainly deals with Leaf Springs, Air Springs, Xihu (West Lake) Dis. Arms, Shock Absorbers, Trailer Suspension, Axles, Brake Drums, Brake Linings, Steel Wheels, Tires, and other products. Since its establishment, the company has always focused on the research and development and operation of truck parts and components, with a variety of operating characteristics and the principle of small profits and high sales, favored by the majority of customers.

The company’s sales of trailer suspension parts and truck chassis parts have covered dozens of countries and regions in South America, North America, Europe, Asia, Africa, and Oceania.

The company advocates “make the work effective, make the staff have achievements”, focuses on staff training and development, constantly introduces advanced management concepts, optimizes and innovates the management mode, reasonably allocates resources, improves the team’s efficiency, and helps the staff to realize their self-worth.

The company will always adhere to the values of “responsibility & win-win”, not obsessed with ineffective competition, but only focus on the pursuit of quality and customer satisfaction, and take action to fulfill the commitment and contribution to society so that Cavwo becomes a respected brand in the global automotive aftermarket.

FAQ

Q1: What material of the leaf spring can you supply?

A: We can supply different materials of leaf spring, including 60Si2Mn, SUP9,50CrV, 51CrV4, or any material as you require. Before placing the order, please make sure the material to us or we can advise the material to you according to your specification.

Q2: How about the quality of your product?

A: Our products are certified to ISO9001, TS16949 international quality standards.

Q3:Could we print our own logo or label on the springs?

A: Yes, you can. We support logo print & label print & stamping.

Q4. How about your delivery time?

A: Generally, it will take 20 to 30 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Truck Suspension |

|---|---|

| Certification: | ISO/TS16949 |

| ABS: | Without ABS |

| Color: | Customized |

| Condition: | New |

| Material: | Steel |

| Customization: |

Available

|

|

|---|

Can trailer suspensions be customized for specific trailer types or load capacities?

Yes, trailer suspensions can be customized to accommodate specific trailer types or load capacities. Here’s a detailed explanation:

Trailer suspensions are available in various configurations, and manufacturers often provide options that can be tailored to meet specific requirements. Customization allows trailer owners to select suspensions that are best suited for their particular trailer type and intended use.

Here are some ways in which trailer suspensions can be customized:

- Load Capacity: Trailer suspensions can be designed and rated to handle different load capacities. The suspension components, such as springs, axles, and shock absorbers, can be specified to match the anticipated weight of the trailer’s cargo. This ensures that the suspension system provides adequate support and maintains proper ride height under the expected load.

- Suspension Type: Different types of suspensions are available, and the choice depends on the specific trailer type and requirements. For example, leaf spring suspensions are commonly used for their durability and load-carrying capacity, while torsion axle suspensions provide excellent shock absorption and improved ride quality. By selecting the appropriate suspension type, trailer owners can optimize the performance and characteristics of their trailers.

- Configuration and Geometry: Trailer suspensions can be customized in terms of their configuration and geometry. This includes the number and arrangement of springs, the placement of axles, and the overall design of the suspension system. For instance, trailers carrying heavy loads may benefit from a dual-axle configuration for better weight distribution and increased stability.

- Adjustability: Some trailer suspensions offer adjustability features that allow fine-tuning based on specific needs. For example, air suspensions provide adjustable ride height and stiffness, allowing users to adapt the suspension to different load conditions. This adjustability enhances versatility and performance.

- Specialized Requirements: In certain cases, trailer suspensions may need to be customized to meet specialized requirements. This could include factors such as off-road capabilities, specific industry standards, or unique environmental conditions. Manufacturers can work with trailer owners to design and build suspensions that meet these specific needs.

It’s important to note that customization options may vary depending on the manufacturer and the specific suspension system. Working with reputable trailer manufacturers or suspension specialists can help ensure that the customization is done correctly and in accordance with industry standards.

In summary, trailer suspensions can be customized to match specific trailer types or load capacities. By selecting the appropriate suspension components, type, configuration, adjustability options, and addressing specialized requirements, trailer owners can optimize the performance, safety, and overall functionality of their trailers.

What are the signs that indicate a need for trailer suspension replacement or maintenance, and how can they be diagnosed?

Recognizing signs of trailer suspension issues is crucial for timely replacement or maintenance to ensure safe and efficient towing operations. Here are common signs and how to diagnose them:

- 1. Uneven Tire Wear: Uneven tire wear, such as cupping or feathering, can indicate suspension problems. Inspect the tires for unusual wear patterns, and if you notice uneven wear, it may suggest misalignment or worn suspension components.

- 2. Excessive Bouncing: If the trailer bounces excessively while in motion, it may be a sign of worn-out shock absorbers or dampers. You can diagnose this by observing the trailer’s behavior while driving on a smooth road. If it continues to bounce after encountering bumps, the shocks may need replacement.

- 3. Squeaking or Clunking Noises: Unusual noises, such as squeaks or clunks, coming from the suspension while driving can indicate worn or damaged components. You can diagnose this by having someone bounce the trailer while you listen for noises, or by performing a visual inspection for loose or damaged parts.

- 4. Poor Handling and Steering: Difficulty in handling or steering the trailer, especially during turns, can be a sign of suspension problems. Uneven handling or drifting may indicate suspension misalignment or worn-out components. Test the trailer’s handling by driving on a straight road and checking for any deviations.

- 5. Excessive Trailer Sway: If the trailer sways excessively from side to side, it may indicate suspension issues. This can be dangerous and is often a result of imbalanced weight distribution or worn-out suspension components. Diagnosis involves inspecting the suspension for damage and ensuring proper load distribution.

- 6. Fluid Leaks: Fluid leaks from shock absorbers or dampers are a clear sign of component failure. Inspect the shocks for visible leaks, which can often be diagnosed by oil residue or wetness around the shock body.

- 7. Sagging Suspension: A visibly sagging or lower-than-normal suspension can indicate weakened springs or overloaded suspension components. A visual inspection can quickly reveal if the suspension is not maintaining its proper ride height.

- 8. Excessive Play: When manually rocking or pushing the trailer, excessive play or movement in suspension components, such as bushings or pivot points, can suggest wear or damage. Hands-on inspection can help identify these issues.

Diagnosing trailer suspension problems typically involves a combination of visual inspection, listening for unusual noises, and observing the trailer’s behavior while driving. Regular maintenance and inspections can help detect issues early and prevent more extensive damage or accidents.

If you encounter any of these signs, it’s advisable to have the trailer suspension inspected by a qualified mechanic or technician who can provide a thorough diagnosis and recommend necessary maintenance or replacement.

How does the design of a trailer suspension impact the overall stability and comfort during towing?

The design of a trailer suspension has a significant impact on the overall stability and comfort during towing. Here’s a detailed explanation:

- Stability:

- 1. Weight Distribution: A well-designed suspension system ensures proper weight distribution across the trailer’s axles. It helps distribute the load evenly, preventing excessive weight on one axle and reducing the risk of overloading. Proper weight distribution enhances stability by maintaining the trailer’s balance and reducing the likelihood of swaying or fishtailing.

- 2. Center of Gravity: The suspension design plays a crucial role in managing the trailer’s center of gravity. A lower center of gravity improves stability by reducing the trailer’s tendency to tip or sway. Suspension systems with lower mounting points or those that incorporate features like torsion axles or independent suspension help lower the center of gravity and enhance overall stability.

- 3. Suspension Geometry: The geometry of the suspension system impacts stability by influencing factors such as wheel alignment, tracking, and roll resistance. A well-designed suspension geometry ensures that the wheels track properly, minimizing sideways movement and improving stability during turns or lane changes.

- 4. Damping Capability: The suspension design affects the damping capability, which refers to the system’s ability to absorb and dissipate shocks. Effective shock absorption reduces the transfer of vertical forces to the trailer, minimizing bouncing, oscillation, and excessive vertical movement. This helps maintain stability by preventing the trailer from becoming unsettled on uneven roads or encountering destabilizing forces.

- Comfort:

- 1. Shock Absorption: A well-designed suspension system effectively absorbs shocks and vibrations caused by road irregularities, bumps, or potholes. It utilizes components such as springs and shock absorbers to cushion the trailer, providing a smoother and more comfortable ride. Effective shock absorption reduces the jolts and vibrations felt inside the towing vehicle and minimizes the transfer of these forces to the cargo being transported.

- 2. Ride Quality: The suspension design influences the overall ride quality of the trailer. A suspension system that balances load support and shock absorption provides a more comfortable towing experience. It reduces excessive bouncing, pitching, or swaying, enhancing comfort for both the driver and passengers in the towing vehicle.

- 3. Noise and Vibration: A well-designed suspension system helps minimize noise and vibration during towing. It reduces the transmission of road-induced vibrations and impacts to the trailer’s frame and components. This results in a quieter and smoother ride, enhancing overall comfort and reducing driver fatigue.

- 4. Trailer Sway: The design of the suspension system can impact the trailer’s susceptibility to sway. Suspension systems that incorporate features like sway control mechanisms, independent suspension, or torsion axles offer improved resistance against trailer sway, enhancing stability and comfort during towing.

The design of the trailer suspension directly affects the stability of the trailer during towing:

The design of the trailer suspension also impacts the comfort experienced during towing:

In summary, the design of a trailer suspension significantly influences the overall stability and comfort during towing. A well-designed suspension system ensures proper weight distribution, manages the center of gravity, optimizes suspension geometry, and provides effective shock absorption. It enhances stability by reducing swaying, improving tracking, and minimizing vertical movement. Additionally, it improves comfort by absorbing shocks, reducing noise and vibration, and minimizing trailer sway. Choosing a suitable suspension design that meets the specific towing requirements is essential for achieving a stable and comfortable towing experience.

editor by Dream 2024-04-30