Product Description

Company Profile

HangZhou Hilite Auto Parts Co., Ltd., Established In 2012, Professional Chinese Supplier Of Trailer Parts, Truck Parts And Agricultural Vehicle Parts. We Are a Professional & Modern Company Who Specializes In R&D, Production And Sales Of Leaf Spring ,Axles, Suspension,Brake System(Relay Valve,Abs…),Tank Trailer Accessories,Etc.

Our Advantages

Our Products Are Mainly Sold To Southeast Asia, Europe, Central And South America, The Middle East And Africa. Our Value Is To Gain More Market Share By Profit&Value Delivery Our Customers And Partners. CHINAMFG Parts is Compatible with BP / Fw Accessories, Can Be Couple with SINOTRUCK/BENZ/FAW/XIHU (WEST LAKE) DIS.FENG… Trucks & Trailers. CHINAMFG Is Committed To Providing Customer With Professional And Precise Services, High-Quality Products with Sufficient Experiecne.

OEM & Packing

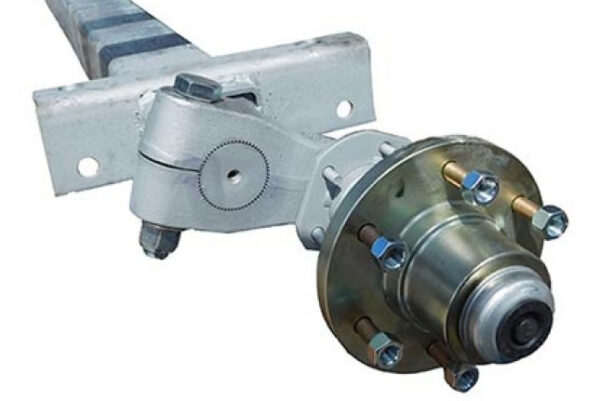

Product Description

| Model | H1(mm) | H2(mm) | L1(mm) | L2(mm) | L3(mm) | L4(mm) | L5(mm) | H(mm) | Axle load(kg) |

| HLT-9AC11 | 415 | 406 | 485 | 1310 | 495 | 1135 | 1155 | 130 | 13,000*2/3/4/5 |

| HLT-9AC12 | 435 | 426 | 485 | 1310 | 495 | 1135 | 1155 | 150 | 13,000*2/3/4/5 |

| HLT-9AC13 | 465 | 456 | 485 | 1310 | 495 | 1135 | 1155 | 180 | 13,000*2/3/4/5 |

| HLT-9AC14 | 495 | 486 | 485 | 1310 | 495 | 1135 | 1155 | 210 | 13,000*2/3/4/5 |

| HLT-9AC15 | 515 | 506 | 485 | 1310 | 495 | 1135 | 1155 | 230 | 13,000*2/3/4/5 |

| HLT-9AC16 | 535 | 526 | 485 | 1310 | 495 | 1135 | 1155 | 250 | 13,000*2/3/4/5 |

| HLT-9AC17 | 555 | 546 | 485 | 1310 | 495 | 1135 | 1155 | 270 | 13,000*2/3/4/5 |

| HLT-9AC18 | 585 | 576 | 485 | 1310 | 495 | 1135 | 1155 | 300 | 13,000*2/3/4/5 |

| HLT-9AC19 | 605 | 596 | 485 | 1310 | 495 | 1135 | 1155 | 320 | 13,000*2/3/4/5 |

| HLT-9AC20 | 635 | 626 | 485 | 1310 | 495 | 1135 | 1155 | 350 | 13,000*2/3/4/5 |

CHINAMFG Specializes In R&D, Production And Sales Of Auto Leaf Springs, American &German Axles, Leaf Spring Suspensions, Air Suspensions, Hydraulic Suspensions, Rigid Suspensions And Other Types Of Suspensions, Single/Double Landing Gear, Electric Landing Gear, Hydraulic Landing Gear And Various Types Of Landing Gear , As Well As Tank Trailer Accessories Such As Manhole Covers, Discharge Valves, Subsea Valves, Etc. 500,000+ Types, One Stop Shopping For All.

Quality Comparasion

. Tandem, Tridem, Quad, All Are Available.

. From 12 Tons To 20 Tons Capacity To Meet Different Requirements

. Different Rh Are Available.

. Different Leaf Spring Are Available.

. Greaseless Powdered Metal Bushing For High Durability

. High Strength Material For Longer Life At Higher Loads

. Simple Maintenance

Certifications

CHINAMFG Provide Guaranteed Services For All Products, Respect And Pay Attention To The Opinions Of Customers And Partners, Including Customizing And Developing New Products According To Customers’ Requirements, Believing Customer Satisfaction Is Our CHINAMFG Pursuit. More Than 76% Of The Customers Who Have Used Hilite Products Have Become Our Loyal Customers, Who Have Established An Incredible Brand Effect For Us In The Local Area.

Factory View

We Would Like To Cooperate With You To Create More New Bonds In The Future.

FAQ

1Q: CAN YOU DESIGN AND PRODUCE THE PRODUCTS WE WANT?

A:We Have Rich Experience And Strong Technical Support To Design And Produce By Your Samples Or Drawings.Warmly Welcomed For Your Samples Or Drawing.

2Q:WHAT’S THE PROCESS OF PURCHASING ORDERS FROM YOU?

A:1.Send Us Your Specific Demand,Such As Oem Numbers, Photos, Trailer Models,Ect.

2.Confirm Our Quotation With Photos And Other Detials.

3.Negotiate About All Details You Need: Packing, Delivery Terms,Warranty, Ect.

4.Sign The Contract For The Payment,We Will Make The Production On Time.

3Q.WHAT IS YOUR TERMS OF PAYMENT?

A: T/T 30% As Deposit, And 70% Before Delivery.

L/C,T/T,D/P, Western Union,Paypal,Money Gram, Others

Photos And Videos Of The Products Will Be Provided Before Your Balance Payment.

4Q :WE WANT TO TRY IN A SMALL QUANTITY AS TRIAL ORDER,BUT LESS THAN YOUR MOQ. WHAT IS YOUR POLICY?

Sample Test And Sample Orders Could Be Accepted If We Have Ready Parts In Stock. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 12months |

|---|---|

| Warranty: | 12months |

| Material: | Carbon |

| Certification: | ISO10012, BSCI, GMP, GSV, ISO13485, OHSAS18001, ISO14001, ISO/TS16949, ISO9001 |

| Position: | Rear |

| OEM: | Yes |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Please answer in detail: What maintenance practices are recommended for trailer suspensions to ensure optimal functionality?

Proper maintenance of trailer suspensions is crucial to ensure optimal functionality, enhance safety, and extend the lifespan of components. Here are recommended maintenance practices for trailer suspensions:

- 1. Regular Inspections: Conduct routine visual inspections of the entire suspension system, including springs, hangers, bushings, and mounting hardware. Look for signs of wear, corrosion, or damage. Inspect for loose or missing components and address any issues promptly.

- 2. Lubrication: Ensure that all moving parts, such as bushings and pivot points, are adequately lubricated. Lubrication reduces friction, minimizes wear, and promotes smooth movement. Follow the manufacturer’s recommendations for the type and frequency of lubrication.

- 3. Check Spring Alignment: Verify that leaf springs are correctly aligned and not showing signs of misalignment. Misaligned springs can lead to uneven tire wear and affect the stability of the trailer. Correct any misalignments as needed.

- 4. Inspect Shocks and Dampers: Check shock absorbers or dampers for leaks, visible damage, or signs of reduced effectiveness. Worn or damaged shocks can compromise ride quality and handling. Replace shocks that show signs of wear or failure.

- 5. Monitor Air Suspension Systems: If the trailer is equipped with air suspension, regularly inspect airbags, valves, and associated components. Check for leaks, proper inflation, and ensure that air suspension components are in good working condition. Address any air leaks promptly.

- 6. Torque Check for Fasteners: Periodically check and torque all fasteners, including bolts, nuts, and U-bolts. Loose or improperly tightened fasteners can lead to component failure and compromise the integrity of the suspension system.

- 7. Check Suspension Alignment: Verify that the suspension components are properly aligned. Misaligned components can cause uneven tire wear and affect the handling of the trailer. Correct any alignment issues to ensure even weight distribution.

- 8. Inspect Bushings and Wear Points: Check for wear on bushings and other wear points in the suspension system. Excessive wear can lead to play in the components and affect the trailer’s stability. Replace worn bushings and components as part of routine maintenance.

- 9. Examine Brake Components: Inspect brake components, including drums, pads, and calipers. Ensure that the brakes are functioning correctly and that there is even wear on the brake components. Replace any worn or damaged brake parts promptly.

- 10. Perform Wheel Alignment: Maintain proper wheel alignment to prevent irregular tire wear and ensure straight-line stability. Misaligned wheels can place additional stress on suspension components and lead to premature wear.

- 11. Address Unusual Noises: Pay attention to any unusual noises coming from the suspension during operation. Clunks, squeaks, or rattles may indicate underlying issues. Investigate and address the source of unusual noises promptly.

- 12. Follow Manufacturer Recommendations: Adhere to the manufacturer’s recommended maintenance schedule and guidelines. Manufacturers provide specific instructions for maintaining their suspension systems, and following these recommendations is essential for optimal performance and warranty compliance.

- 13. Consider Professional Inspections: Periodically, consider having the trailer suspension system professionally inspected. Trained technicians can identify potential issues that may not be visible during routine inspections, ensuring comprehensive maintenance.

By incorporating these maintenance practices into a routine schedule, trailer owners and operators can help ensure that the suspension system operates optimally, promoting safety, reliability, and longevity.

Can you provide insights into the importance of proper installation and alignment of trailer suspensions?

Proper installation and alignment of trailer suspensions are critical factors that significantly impact the performance, safety, and longevity of trailers. Here are insights into their importance:

- 1. Safety: Correct installation and alignment ensure that the trailer operates safely. A properly aligned suspension system helps maintain stability during turns, reduces the risk of rollovers, and enhances overall control when towing.

- 2. Even Tire Wear: Proper alignment prevents uneven tire wear, which can lead to premature tire replacement and increased operating costs. By distributing the load evenly, alignment helps extend tire life and improves fuel efficiency.

- 3. Handling and Maneuverability: Accurate alignment enhances the trailer’s handling and maneuverability. It allows for smoother turns and better response to steering inputs, making it easier for the driver to control the trailer, especially in tight spaces or when navigating challenging terrain.

- 4. Reduced Maintenance Costs: Properly installed and aligned suspensions require less maintenance. When components are correctly positioned and functioning as designed, they experience less stress and wear, resulting in fewer repairs and lower maintenance costs over the trailer’s lifespan.

- 5. Load Distribution: Alignment ensures that the weight is evenly distributed across all axles and wheels. This prevents overloading of specific components and helps maintain the structural integrity of the trailer, preventing potential damage or failures.

- 6. Improved Fuel Efficiency: When a trailer’s suspension is correctly aligned, it reduces rolling resistance. Lower rolling resistance means less effort is required to tow the trailer, which translates into improved fuel efficiency and cost savings over time.

- 7. Enhanced Ride Comfort: Proper alignment contributes to a smoother and more comfortable ride for the driver and minimizes cargo movement within the trailer. This is particularly important when transporting delicate or sensitive goods.

- 8. Regulatory Compliance: In many regions, there are regulations and standards that govern trailer alignment and suspension installation. Adhering to these regulations ensures compliance with safety and roadworthiness requirements, preventing potential legal issues.

- 9. Extended Equipment Lifespan: Correctly installed and aligned suspensions reduce stress on components, such as axles, springs, and bearings. This, in turn, extends the lifespan of these critical parts, reducing the need for premature replacements.

- 10. Overall Performance: Proper installation and alignment contribute to the overall performance of trailers. Whether it’s hauling heavy loads or ensuring a smooth ride for sensitive cargo, alignment plays a pivotal role in achieving the desired performance outcomes.

In conclusion, the proper installation and alignment of trailer suspensions are essential for safety, efficiency, and cost-effectiveness. Neglecting these aspects can lead to a range of issues, from increased maintenance expenses to compromised safety on the road. Therefore, it’s crucial for trailer operators to prioritize and regularly check the installation and alignment of their suspension systems.

Can you explain the primary functions and importance of trailer suspension in towing?

Trailer suspension plays a critical role in towing operations by providing several primary functions and offering overall importance. Here’s a detailed explanation:

- Primary Functions:

- 1. Load Support: One of the primary functions of trailer suspension is to support the weight of the trailer and its cargo. It distributes the weight evenly across the axles, ensuring that no single axle or tire bears an excessive load. This helps prevent overloading, improves stability, and enhances the overall towing experience.

- 2. Shock Absorption: Trailer suspension is responsible for absorbing shocks and vibrations that occur during towing. It consists of various components such as springs, shock absorbers, and airbags that work together to cushion the trailer against road irregularities, bumps, and potholes. By absorbing these shocks, the suspension system reduces the impact transferred to the trailer, providing a smoother and more comfortable ride.

- 3. Stability and Control: Another crucial function of trailer suspension is to maintain stability and control during towing. It helps to keep the trailer level and balanced, preventing excessive swaying, fishtailing, or bouncing. By providing proper weight distribution and managing the trailer’s center of gravity, the suspension system enhances overall stability, making the trailer easier to control and reducing the risk of accidents or loss of control.

- 4. Traction Enhancement: The suspension system contributes to improved traction, especially in challenging road conditions. It helps keep the trailer’s tires in contact with the road surface, maximizing grip and minimizing the chances of slipping or skidding. This is particularly important when towing on uneven or slippery terrains, as the suspension system ensures better traction, enhancing overall safety and maneuverability.

- Importance:

- 1. Safety: Trailer suspension is of utmost importance for towing safety. It helps maintain stability, control, and proper weight distribution, reducing the risk of accidents or loss of control. By absorbing shocks and vibrations, it also minimizes the potential for cargo damage and improves road grip, especially during emergency braking or evasive maneuvers.

- 2. Comfort: A well-designed and properly functioning suspension system enhances the comfort of both the driver and passengers in the towing vehicle. By absorbing road shocks and vibrations, it reduces the jolts, bumps, and vibrations felt inside the vehicle, providing a smoother and more pleasant ride.

- 3. Protection of Cargo: The suspension system helps protect the cargo being transported on the trailer. By absorbing shocks and minimizing vibrations, it reduces the risk of damage to fragile or sensitive cargo. This is particularly important when transporting goods that are susceptible to impact or vibration-related damage.

- 4. Longevity of Trailer Components: Properly functioning trailer suspension reduces the strain on various trailer components, including the frame, axles, tires, and other critical parts. By distributing loads and cushioning impacts, it helps minimize wear and tear, extending the lifespan of these components and reducing the need for repairs or replacements.

In conclusion, trailer suspension serves essential functions in towing operations. It provides load support, absorbs shocks, enhances stability and control, and improves traction. The importance of trailer suspension lies in ensuring towing safety, providing comfort, protecting the cargo, and prolonging the lifespan of trailer components. Regular maintenance and inspection of the suspension system are crucial to ensure its optimal performance and to enjoy a safe and smooth towing experience.

editor by CX 2024-03-02