Product Description

Main Products

Main Products

Product Description

Product Description

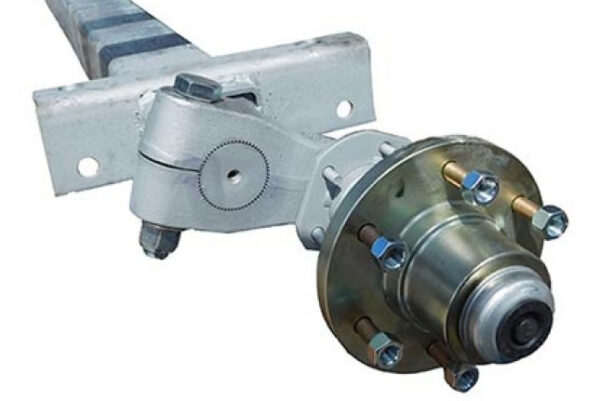

With hundreds of thousands of Yonglitai Beam Air Suspensions on trailers running on- and off-road around the world, these models have been the suspensions of choice for virtually every trailer application for nearly a decade. The Yonglitai delivers rugged dependability and outstanding ride quality and control for vans, platforms, dumps, tankers, dollies and pups, lowboys, auto haulers, trailers on flat cars, B-trains, Michigan trains and container chassis. Our patented CHINAMFG Bushing in unison with a rigid beam and CHINAMFG axle connection provides the ideal combination of ride softness and roll stability.

Yonglitai’s proprietary heavy-section material and forming experience gave birth to innovative solutions for the popular Beam Air Suspensions in demand today. Years of product research and development have resulted in efficient suspension main support members that provide excellent ride without sacrificing handling.

Product Parameters

Product Parameters

| Capacity | 9T – 13T | Brand Name | L1 |

| Material | Alloy steel+Special industrial rubber | Payment Terms | T/T, Western union,L/C…. |

| Supply Ability | 150000PCS axles /50000sets suspensions each year | MOQ | One container/50-60pics axle/5-12ets axle assembly |

| Production Time | 15days | Warranty | 12 months |

| Port | HangZhou San Shui, Jiu Jiang | Common model | 15 models |

Product Features

Product Features

Safety and comfort: Effectively absorb the vibration generated when the vehicle is running and effectively protect the transported goods.

Performance boost: Axle load distribution on each axle is uniform.The contact between the tire and the road surface is more balanced, which can improve the overall braking performance and stability of the vehicle when cornering!

Reduce wear and tear: effectively protect the frame (such as tanks and boxes), axles, tires, etc., reduce the wear and tear of parts, and reduce vehicle maintenance costs.

When no load, the use of the lifting device can effectively lower the Low tire wear reduces fuel consumption.

Long-term economy: The air suspension is safe, stable, efficient, widely used, and has a long maintenance cycle, which brings long-term economic benefits to the safe operation of logistics companies.

High cost performance:With boutique quality and high-quality service, the parts of the product are designed and produced independently, with high self-made rate, controllable cost and affordable price.

Reliability: The company develops and produces in strict accordance with the IATF 16949/ISO9001 system, and fully guarantees the quality of the products

Low maintenance costs:There are hundreds of service points nationwide, and all major provinces and cities can experience our high-quality services at affordable prices.

Complete range:German and American axle series and tandem suspension, air suspension, bogie, rigid suspension, 4 suspension series, a total of more than 100 products.

Customized design: Customized design is available for we own the most powerful technician and development team in China. We can develop new products and modify traditional products according to your requirements.

Delivery date assure: We have a total area of 300 thousand square CHINAMFG production base to ensure your products deliver to you in time.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 24 Hour Online |

|---|---|

| Material: | Alloy Steel & Special Industrial Rubber |

| Certification: | ISO/TS16949, ISO9001, SGS |

| Position: | Rear |

| OEM: | Yes |

| Type: | Air Suspension |

| Customization: |

Available

|

|

|---|

Please answer in detail: What maintenance practices are recommended for trailer suspensions to ensure optimal functionality?

Proper maintenance of trailer suspensions is crucial to ensure optimal functionality, enhance safety, and extend the lifespan of components. Here are recommended maintenance practices for trailer suspensions:

- 1. Regular Inspections: Conduct routine visual inspections of the entire suspension system, including springs, hangers, bushings, and mounting hardware. Look for signs of wear, corrosion, or damage. Inspect for loose or missing components and address any issues promptly.

- 2. Lubrication: Ensure that all moving parts, such as bushings and pivot points, are adequately lubricated. Lubrication reduces friction, minimizes wear, and promotes smooth movement. Follow the manufacturer’s recommendations for the type and frequency of lubrication.

- 3. Check Spring Alignment: Verify that leaf springs are correctly aligned and not showing signs of misalignment. Misaligned springs can lead to uneven tire wear and affect the stability of the trailer. Correct any misalignments as needed.

- 4. Inspect Shocks and Dampers: Check shock absorbers or dampers for leaks, visible damage, or signs of reduced effectiveness. Worn or damaged shocks can compromise ride quality and handling. Replace shocks that show signs of wear or failure.

- 5. Monitor Air Suspension Systems: If the trailer is equipped with air suspension, regularly inspect airbags, valves, and associated components. Check for leaks, proper inflation, and ensure that air suspension components are in good working condition. Address any air leaks promptly.

- 6. Torque Check for Fasteners: Periodically check and torque all fasteners, including bolts, nuts, and U-bolts. Loose or improperly tightened fasteners can lead to component failure and compromise the integrity of the suspension system.

- 7. Check Suspension Alignment: Verify that the suspension components are properly aligned. Misaligned components can cause uneven tire wear and affect the handling of the trailer. Correct any alignment issues to ensure even weight distribution.

- 8. Inspect Bushings and Wear Points: Check for wear on bushings and other wear points in the suspension system. Excessive wear can lead to play in the components and affect the trailer’s stability. Replace worn bushings and components as part of routine maintenance.

- 9. Examine Brake Components: Inspect brake components, including drums, pads, and calipers. Ensure that the brakes are functioning correctly and that there is even wear on the brake components. Replace any worn or damaged brake parts promptly.

- 10. Perform Wheel Alignment: Maintain proper wheel alignment to prevent irregular tire wear and ensure straight-line stability. Misaligned wheels can place additional stress on suspension components and lead to premature wear.

- 11. Address Unusual Noises: Pay attention to any unusual noises coming from the suspension during operation. Clunks, squeaks, or rattles may indicate underlying issues. Investigate and address the source of unusual noises promptly.

- 12. Follow Manufacturer Recommendations: Adhere to the manufacturer’s recommended maintenance schedule and guidelines. Manufacturers provide specific instructions for maintaining their suspension systems, and following these recommendations is essential for optimal performance and warranty compliance.

- 13. Consider Professional Inspections: Periodically, consider having the trailer suspension system professionally inspected. Trained technicians can identify potential issues that may not be visible during routine inspections, ensuring comprehensive maintenance.

By incorporating these maintenance practices into a routine schedule, trailer owners and operators can help ensure that the suspension system operates optimally, promoting safety, reliability, and longevity.

How does the choice of trailer suspensions affect the overall performance and reliability of a trailer?

The choice of trailer suspensions has a significant impact on the overall performance and reliability of a trailer. It influences various aspects of trailer operation and functionality. Here’s how:

- 1. Load Capacity: The type and design of trailer suspensions determine the trailer’s load-carrying capacity. Choosing suspensions with the appropriate load rating ensures that the trailer can safely carry the intended cargo without overloading or straining the suspension components.

- 2. Ride Quality: The choice of suspensions affects the ride quality for both the trailer and the cargo. A well-matched suspension system can provide a smoother and more stable ride, reducing the risk of cargo damage and enhancing driver comfort.

- 3. Handling and Maneuverability: Different suspension systems offer varying levels of handling and maneuverability. Some suspensions are designed for stability during high-speed highway travel, while others excel in off-road or rugged terrain. Choosing the right suspension type ensures optimal handling characteristics.

- 4. Durability and Longevity: The quality and construction of trailer suspensions play a vital role in their durability. High-quality suspensions are less prone to wear and are designed to withstand the rigors of heavy-duty use, resulting in longer service life and increased reliability.

- 5. Maintenance Requirements: The maintenance needs of trailer suspensions can vary depending on their type and design. Some suspensions require more frequent lubrication and inspection, while others are designed for minimal maintenance. Selecting suspensions that align with your maintenance capabilities can affect long-term reliability.

- 6. Adaptability to Terrain: The choice of suspensions impacts the trailer’s adaptability to different terrains. Air suspensions, for example, excel in providing a smooth ride on rough or uneven surfaces, enhancing versatility and reliability in various settings.

- 7. Safety: Properly matched suspensions contribute to trailer safety. A well-balanced suspension system helps prevent trailer sway, reduces the risk of rollovers, and enhances stability during emergency maneuvers, improving overall safety.

- 8. Fuel Efficiency: Some suspensions are designed to minimize rolling resistance, which can improve fuel efficiency. Choosing fuel-efficient suspensions can lead to cost savings over the trailer’s operational lifespan.

- 9. Compatibility with Towing Vehicle: The choice of trailer suspensions should consider the towing vehicle’s specifications. Ensuring compatibility between the trailer suspensions and the towing vehicle’s capabilities is essential for safe and reliable towing.

- 10. Load Distribution: Trailer suspensions play a critical role in distributing the weight of the cargo evenly across the axles. Proper load distribution enhances stability, prevents overloading, and reduces the risk of component wear or failure.

In summary, the choice of trailer suspensions directly impacts the trailer’s performance, reliability, and safety. It’s essential to carefully consider factors such as load capacity, terrain, maintenance requirements, and intended use when selecting suspensions to ensure that they align with the specific needs of your trailer and operational requirements.

In what types of trailers are suspensions commonly used, and how do they vary?

Suspensions are commonly used in various types of trailers to provide support, stability, and shock absorption. Here’s a detailed explanation:

- Types of Trailers:

- 1. Utility Trailers: Utility trailers, including flatbed trailers, equipment trailers, and landscape trailers, often feature suspensions. These trailers are designed to transport a wide range of materials, equipment, or goods and require suspensions to ensure load support, stability, and a smoother ride.

- 2. Enclosed Trailers: Enclosed trailers, such as cargo trailers and box trailers, are commonly equipped with suspensions. These trailers are used for transporting goods that require protection from the elements and benefit from suspensions to absorb shocks, enhance stability, and protect the cargo.

- 3. Livestock Trailers: Livestock trailers, used for transporting animals, typically have suspensions to provide a smoother ride and minimize stress on the animals. The suspensions help absorb shocks and vibrations, ensuring the well-being and safety of the livestock during transportation.

- 4. RV Trailers: Recreational vehicles (RVs), including travel trailers and fifth-wheel trailers, utilize suspensions to enhance comfort and stability. These trailers are designed for living and leisure purposes and benefit from suspensions to provide a smoother ride, reduce vibrations, and improve overall towing experience.

- 5. Boat Trailers: Boat trailers, used for transporting boats to and from the water, often feature suspensions. These suspensions help absorb road shocks and vibrations, ensuring the safety of the boat during transportation and minimizing potential damage to the hull and other components.

- Variations in Suspensions:

- 1. Leaf Spring Suspension: Leaf spring suspensions are widely used in trailers and consist of multiple layers of curved metal strips (leaves) that flex and absorb shocks. They are known for their durability, load-carrying capacity, and cost-effectiveness.

- 2. Coil Spring Suspension: Coil spring suspensions use helical coil springs to provide support and shock absorption. They offer a smoother ride and are commonly used in trailers that require improved comfort, such as RVs or enclosed trailers.

- 3. Torsion Axle Suspension: Torsion axle suspensions use a rubberized torsion arm system to provide independent suspension for each wheel. They offer excellent shock absorption, improved stability, and are commonly used in utility trailers and RVs.

- 4. Air Suspension: Air suspensions utilize airbags to support the trailer’s weight and provide adjustable suspension stiffness. They offer a high level of adjustability, enhanced ride quality, and are commonly used in heavy-duty trailers or specialized applications.

- 5. Independent Suspension: Independent suspensions allow each wheel to move independently, providing superior shock absorption and stability. They are commonly used in high-end trailers, including luxury RVs or high-performance trailers.

Suspensions are commonly found in the following types of trailers:

Suspensions used in trailers can vary based on their design, construction, and intended use. Here are some common variations:

In summary, suspensions are commonly used in utility trailers, enclosed trailers, livestock trailers, RV trailers, and boat trailers. The choice of suspension varies based on trailer type and requirements. Common variations include leaf spring suspension, coil spring suspension, torsion axle suspension, air suspension, and independent suspension. Each type offers specific benefits in terms of load support, shock absorption, stability, and ride quality, catering to the diverse needs of different trailer applications.

editor by Dream 2024-04-29