Product Description

Product Description

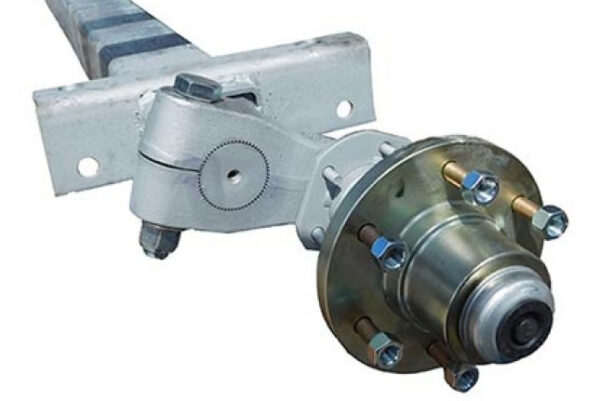

Our trailer suspension are suitable for American and German type trucks.

We can produce American & German axles and suspensions of various specifications according to your drawing, sample or specific parameters you give us.

|

Product Name |

Trailer Air Suspension |

|

Type |

American & German type |

|

Height |

380-500 mm (According to the model) |

|

Material |

Iron |

|

Color |

Black |

|

Package |

Carton, wooden box, pallet |

|

Quality |

Super |

|

Port |

China Port |

|

Payment |

T/T, L/C, D/P, D/A, MoneyGram, Credit Card, PayPal, Western Union |

|

Service air ride trailer axles |

OEM ODM If there is no model you need, |

Man Air Suspension Information :

1.Operational temperature of air bag: -50/55 degree centigrade

2.Compatible width of vehicle frame: 960mm-1200mm

3.The factory has passed theISO and TS16949 standard authentication of international quality control system.

4.strict quality control system to assure our excellent product quality.

5. products are popular in the CHINAMFG market, including North American, South American, European, African and Southeast Asian markets.

During these years, our factory is dedicated to producing and designing. We gained several state-level patents.

The Advantage about Air Suspension:

• Comfortable Riding

• Light Weight

• Variable Ride Height & Fixed Height

• Lowering Maintenance Fee

• Better for Road

• Longer Service Life

• Proven, Trend-setting Suspension

Air Suspension Application:

• Commercial Vehicle and Cars

• Front Axle

• Rear Axle

• Driver Cab

• Driver Seat

1. The air suspension effectively reduces the severe vibration during the operation of the vehicle and ensures the best braking performance of the vehicle.

2. Run smoothly and protect various items from the impact of vehicle operation.

3. Air suspension makes the car adapt to road conditions faster and better.

4. When the vehicle is running with no load, the axle is lifted by the axle lifting device to reduce tire wear.

5. The air suspension lifting device can raise or lower the height of the vehicle for easy unloading.

Product Recommended

Why Choose US

HangZhou Hongruida Trailer Parts Co., Ltd. Mainly produces semi trailer and its related trailer accessories, truck parts, including various types of American type trailer axle, concave axle, spoke axle, German type trailer axle, agricultural axle, American type suspension, single point suspension, rigid suspension, air suspension, leaf spring and landing gear, kingpin, air chamber, air reservoir, etc. Our sales network covers all regions of the world. Both new and old customers support customization.

We have advanced processing technology, first-class production line, professional production quality, high-quality service concept, guarantee your trailer business brighter! Our products are produced strictly in accordance with national implementation standards, with reasonable prices, and the cost performance ratio is far ahead in the industry, which is highly praised by customers!

High quality, competitive price to continue to provide customers witih best products is our constant pursuit. With advanced first class production equipments and high technology engineerings, which make high quality and one-to-1 24 hours full-time service, our products are being exported more than 30 countries with the right to import and export. Welcome your inquiry.

Our Service

1. Advanced equipment and rich experience workers are applied during the whole producing process to ensure the quality of Low bed semi trailer.

2. We have passed ISO9001:2008, CCC, BV, SGS, TUV.

3. We have more than 20 years of experience and a strong team of engineers, we are manufacturer, we could design the product according to your special requirements.

4. We have rest assured after-sales service.

Packaging & Shipping

We usually adopt shipping by bulk cargo, flat rack, container container and Roro ship. We will arrange the most cost-effective transportation mode according to the quantity of products. All trailers will be polished with wax before shipping. We guarantee that all products have gone through strict inspection and are in good condition before shipment. We strive for 100% customer satisfaction on every sale we close.

Delivery time:10-20 working days after payment receipt confirmed (based on actual quantity).

Packing:Standard export packing, or customized packing as your request.

Professional goods shipping forwarder.

FAQ

1. How is the quality of your products?

Our products are manufactured in strict accordance with national and international standards, and we test each product before delivery. If you would like to view our quality certification and various test reports, please contact us.

2. How about price?

We are a factory and able to give you the lowest price. Please trust the quotation we would give you, and it is professional one.

3. Why should you chose us?

Choosing us happens because of quality, then price, and we can give you both. Additionally, we can also offer professional products inquiry,products knowledge train(for agents), smooth goods delivery, excellent customer solution proposals.

4. How to ensure the interests of buyers?

Our company supports Alibaba online trading, which not only ensures the safety of the buyer’s funds, but also guarantees the quality of the goods. From the outbound, to the loading, and finally to the receiving, the whole process is transparent.

5. How to guarantee delivery time?

We are a factory with a large inventory of stock, which guarantees that the goods will be shipped within the shortest time from the date of signing the contract.

6. How to get samples?

We can provide samples for buyer’s testing free of charge, but buyers need to pay for shipping costs.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 1 Year |

|---|---|

| Type: | Air Suspension |

| Certification: | ISO/TS16949, CE |

| Loading Weight: | 15T |

| ABS: | With ABS |

| Tent Type: | Simple |

| Customization: |

Available

|

|

|---|

Please answer in detail: What maintenance practices are recommended for trailer suspensions to ensure optimal functionality?

Proper maintenance of trailer suspensions is crucial to ensure optimal functionality, enhance safety, and extend the lifespan of components. Here are recommended maintenance practices for trailer suspensions:

- 1. Regular Inspections: Conduct routine visual inspections of the entire suspension system, including springs, hangers, bushings, and mounting hardware. Look for signs of wear, corrosion, or damage. Inspect for loose or missing components and address any issues promptly.

- 2. Lubrication: Ensure that all moving parts, such as bushings and pivot points, are adequately lubricated. Lubrication reduces friction, minimizes wear, and promotes smooth movement. Follow the manufacturer’s recommendations for the type and frequency of lubrication.

- 3. Check Spring Alignment: Verify that leaf springs are correctly aligned and not showing signs of misalignment. Misaligned springs can lead to uneven tire wear and affect the stability of the trailer. Correct any misalignments as needed.

- 4. Inspect Shocks and Dampers: Check shock absorbers or dampers for leaks, visible damage, or signs of reduced effectiveness. Worn or damaged shocks can compromise ride quality and handling. Replace shocks that show signs of wear or failure.

- 5. Monitor Air Suspension Systems: If the trailer is equipped with air suspension, regularly inspect airbags, valves, and associated components. Check for leaks, proper inflation, and ensure that air suspension components are in good working condition. Address any air leaks promptly.

- 6. Torque Check for Fasteners: Periodically check and torque all fasteners, including bolts, nuts, and U-bolts. Loose or improperly tightened fasteners can lead to component failure and compromise the integrity of the suspension system.

- 7. Check Suspension Alignment: Verify that the suspension components are properly aligned. Misaligned components can cause uneven tire wear and affect the handling of the trailer. Correct any alignment issues to ensure even weight distribution.

- 8. Inspect Bushings and Wear Points: Check for wear on bushings and other wear points in the suspension system. Excessive wear can lead to play in the components and affect the trailer’s stability. Replace worn bushings and components as part of routine maintenance.

- 9. Examine Brake Components: Inspect brake components, including drums, pads, and calipers. Ensure that the brakes are functioning correctly and that there is even wear on the brake components. Replace any worn or damaged brake parts promptly.

- 10. Perform Wheel Alignment: Maintain proper wheel alignment to prevent irregular tire wear and ensure straight-line stability. Misaligned wheels can place additional stress on suspension components and lead to premature wear.

- 11. Address Unusual Noises: Pay attention to any unusual noises coming from the suspension during operation. Clunks, squeaks, or rattles may indicate underlying issues. Investigate and address the source of unusual noises promptly.

- 12. Follow Manufacturer Recommendations: Adhere to the manufacturer’s recommended maintenance schedule and guidelines. Manufacturers provide specific instructions for maintaining their suspension systems, and following these recommendations is essential for optimal performance and warranty compliance.

- 13. Consider Professional Inspections: Periodically, consider having the trailer suspension system professionally inspected. Trained technicians can identify potential issues that may not be visible during routine inspections, ensuring comprehensive maintenance.

By incorporating these maintenance practices into a routine schedule, trailer owners and operators can help ensure that the suspension system operates optimally, promoting safety, reliability, and longevity.

Can you share tips for improving the longevity and performance of trailer suspensions in towing applications?

Maintaining and enhancing the longevity and performance of trailer suspensions in towing applications is essential for safe and efficient operation. Here are some valuable tips to achieve this:

- 1. Regular Inspections: Conduct frequent visual inspections of the trailer suspensions. Look for signs of wear, damage, or corrosion on components such as springs, shocks, and mounting hardware. Address any issues promptly to prevent further damage.

- 2. Lubrication: Ensure that all moving parts, including bushings and pivot points, are adequately lubricated. Proper lubrication reduces friction, minimizes wear, and extends the lifespan of suspension components. Follow the manufacturer’s recommendations for lubrication intervals and types of lubricants.

- 3. Maintain Proper Alignment: Verify that the trailer’s suspension components, including axles and wheels, are correctly aligned. Misalignment can lead to uneven tire wear and affect handling. Correct any alignment issues to ensure even weight distribution.

- 4. Inspect Shock Absorbers or Dampers: Regularly check shock absorbers or dampers for leaks, visible damage, or signs of reduced effectiveness. Worn or damaged shocks can compromise ride quality and handling. Replace them when necessary.

- 5. Monitor Air Suspension Systems: If the trailer uses air suspension, inspect airbags, valves, and associated components for leaks, proper inflation, and overall condition. Address air leaks promptly to maintain suspension performance.

- 6. Torque Fasteners: Periodically check and torque all fasteners, including bolts, nuts, and U-bolts. Loose or improperly tightened fasteners can lead to component failure and compromise suspension integrity.

- 7. Proper Load Distribution: Ensure that cargo is loaded and distributed evenly within the trailer. Overloading or uneven weight distribution can strain suspension components and lead to premature wear.

- 8. Maintain Brake Components: Inspect brake components, including drums, pads, and calipers. Ensure that the brakes are functioning correctly and that there is even wear on the brake components. Replace any worn or damaged brake parts promptly.

- 9. Wheel Alignment: Maintain proper wheel alignment to prevent irregular tire wear and ensure straight-line stability. Misaligned wheels can place additional stress on suspension components and lead to premature wear.

- 10. Address Unusual Noises: Pay attention to any unusual noises coming from the suspension during operation. Clunks, squeaks, or rattles may indicate underlying issues. Investigate and address the source of unusual noises promptly.

- 11. Follow Manufacturer Recommendations: Adhere to the manufacturer’s recommended maintenance schedule and guidelines. Manufacturers provide specific instructions for maintaining their suspension systems, and following these recommendations is essential for optimal performance and warranty compliance.

- 12. Consider Professional Inspections: Periodically, consider having the trailer suspension system professionally inspected. Trained technicians can identify potential issues that may not be visible during routine inspections, ensuring comprehensive maintenance.

By incorporating these maintenance practices into a routine schedule, trailer owners and operators can help ensure that the suspension system operates optimally, promoting safety, reliability, and longevity in towing applications.

Can you explain the primary functions and importance of trailer suspension in towing?

Trailer suspension plays a critical role in towing operations by providing several primary functions and offering overall importance. Here’s a detailed explanation:

- Primary Functions:

- 1. Load Support: One of the primary functions of trailer suspension is to support the weight of the trailer and its cargo. It distributes the weight evenly across the axles, ensuring that no single axle or tire bears an excessive load. This helps prevent overloading, improves stability, and enhances the overall towing experience.

- 2. Shock Absorption: Trailer suspension is responsible for absorbing shocks and vibrations that occur during towing. It consists of various components such as springs, shock absorbers, and airbags that work together to cushion the trailer against road irregularities, bumps, and potholes. By absorbing these shocks, the suspension system reduces the impact transferred to the trailer, providing a smoother and more comfortable ride.

- 3. Stability and Control: Another crucial function of trailer suspension is to maintain stability and control during towing. It helps to keep the trailer level and balanced, preventing excessive swaying, fishtailing, or bouncing. By providing proper weight distribution and managing the trailer’s center of gravity, the suspension system enhances overall stability, making the trailer easier to control and reducing the risk of accidents or loss of control.

- 4. Traction Enhancement: The suspension system contributes to improved traction, especially in challenging road conditions. It helps keep the trailer’s tires in contact with the road surface, maximizing grip and minimizing the chances of slipping or skidding. This is particularly important when towing on uneven or slippery terrains, as the suspension system ensures better traction, enhancing overall safety and maneuverability.

- Importance:

- 1. Safety: Trailer suspension is of utmost importance for towing safety. It helps maintain stability, control, and proper weight distribution, reducing the risk of accidents or loss of control. By absorbing shocks and vibrations, it also minimizes the potential for cargo damage and improves road grip, especially during emergency braking or evasive maneuvers.

- 2. Comfort: A well-designed and properly functioning suspension system enhances the comfort of both the driver and passengers in the towing vehicle. By absorbing road shocks and vibrations, it reduces the jolts, bumps, and vibrations felt inside the vehicle, providing a smoother and more pleasant ride.

- 3. Protection of Cargo: The suspension system helps protect the cargo being transported on the trailer. By absorbing shocks and minimizing vibrations, it reduces the risk of damage to fragile or sensitive cargo. This is particularly important when transporting goods that are susceptible to impact or vibration-related damage.

- 4. Longevity of Trailer Components: Properly functioning trailer suspension reduces the strain on various trailer components, including the frame, axles, tires, and other critical parts. By distributing loads and cushioning impacts, it helps minimize wear and tear, extending the lifespan of these components and reducing the need for repairs or replacements.

In conclusion, trailer suspension serves essential functions in towing operations. It provides load support, absorbs shocks, enhances stability and control, and improves traction. The importance of trailer suspension lies in ensuring towing safety, providing comfort, protecting the cargo, and prolonging the lifespan of trailer components. Regular maintenance and inspection of the suspension system are crucial to ensure its optimal performance and to enjoy a safe and smooth towing experience.

editor by CX 2024-03-29