Product Description

Product Description

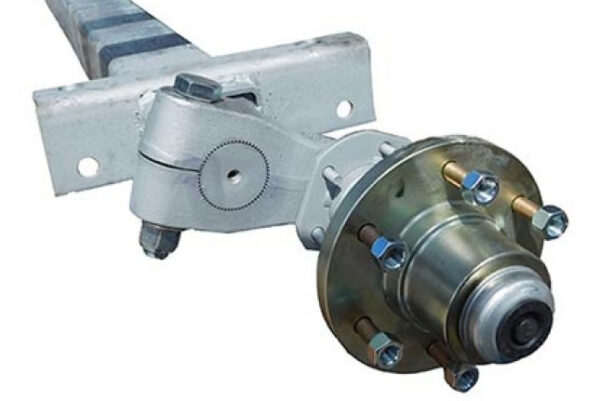

High quality tandem axle 2 axles suspension assembly for trailer

1. Carry greater vertical load and better torque.

2. Easy installation, low price, long service life, low maintenance cost.

3. It is suitable for various road conditions and has many optional specifications.

Hanger Assembly

The suspension is stamped and welded with Q345 steel plate material, which is light in weight and strong in

rigidity. The leaf spring will not shift during use.

Leaf Spring

Suspension can be matched with different width/ thickness/number of pieces, we can recommend the number

of leaf springs according to the load. Use high-quality steel, long life and large load

Company Profile

Other Products

Certifications

The factory has obtained ISO9001 certification and Alibaba SGS certification, and has more

than a dozen patent certificates. It is a famous brand enterprise in China.

Customer Photos

Our company team participates in more than 10 exhibitions at home and abroad every year,

visiting and receiving customers dozens of times, and welcomes every customer’s inquiry and

factory inspection.

Packaging & Shipping

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Rear Axles |

|---|---|

| Certification: | ISO9001 |

| Loading Weight: | 36t |

| Samples: |

US$ 500/units

1 units(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Please answer in detail: What maintenance practices are recommended for trailer suspensions to ensure optimal functionality?

Proper maintenance of trailer suspensions is crucial to ensure optimal functionality, enhance safety, and extend the lifespan of components. Here are recommended maintenance practices for trailer suspensions:

- 1. Regular Inspections: Conduct routine visual inspections of the entire suspension system, including springs, hangers, bushings, and mounting hardware. Look for signs of wear, corrosion, or damage. Inspect for loose or missing components and address any issues promptly.

- 2. Lubrication: Ensure that all moving parts, such as bushings and pivot points, are adequately lubricated. Lubrication reduces friction, minimizes wear, and promotes smooth movement. Follow the manufacturer’s recommendations for the type and frequency of lubrication.

- 3. Check Spring Alignment: Verify that leaf springs are correctly aligned and not showing signs of misalignment. Misaligned springs can lead to uneven tire wear and affect the stability of the trailer. Correct any misalignments as needed.

- 4. Inspect Shocks and Dampers: Check shock absorbers or dampers for leaks, visible damage, or signs of reduced effectiveness. Worn or damaged shocks can compromise ride quality and handling. Replace shocks that show signs of wear or failure.

- 5. Monitor Air Suspension Systems: If the trailer is equipped with air suspension, regularly inspect airbags, valves, and associated components. Check for leaks, proper inflation, and ensure that air suspension components are in good working condition. Address any air leaks promptly.

- 6. Torque Check for Fasteners: Periodically check and torque all fasteners, including bolts, nuts, and U-bolts. Loose or improperly tightened fasteners can lead to component failure and compromise the integrity of the suspension system.

- 7. Check Suspension Alignment: Verify that the suspension components are properly aligned. Misaligned components can cause uneven tire wear and affect the handling of the trailer. Correct any alignment issues to ensure even weight distribution.

- 8. Inspect Bushings and Wear Points: Check for wear on bushings and other wear points in the suspension system. Excessive wear can lead to play in the components and affect the trailer’s stability. Replace worn bushings and components as part of routine maintenance.

- 9. Examine Brake Components: Inspect brake components, including drums, pads, and calipers. Ensure that the brakes are functioning correctly and that there is even wear on the brake components. Replace any worn or damaged brake parts promptly.

- 10. Perform Wheel Alignment: Maintain proper wheel alignment to prevent irregular tire wear and ensure straight-line stability. Misaligned wheels can place additional stress on suspension components and lead to premature wear.

- 11. Address Unusual Noises: Pay attention to any unusual noises coming from the suspension during operation. Clunks, squeaks, or rattles may indicate underlying issues. Investigate and address the source of unusual noises promptly.

- 12. Follow Manufacturer Recommendations: Adhere to the manufacturer’s recommended maintenance schedule and guidelines. Manufacturers provide specific instructions for maintaining their suspension systems, and following these recommendations is essential for optimal performance and warranty compliance.

- 13. Consider Professional Inspections: Periodically, consider having the trailer suspension system professionally inspected. Trained technicians can identify potential issues that may not be visible during routine inspections, ensuring comprehensive maintenance.

By incorporating these maintenance practices into a routine schedule, trailer owners and operators can help ensure that the suspension system operates optimally, promoting safety, reliability, and longevity.

How do trailer suspensions contribute to the adaptability and versatility of trailers in various settings?

Trailer suspensions play a pivotal role in enhancing the adaptability and versatility of trailers across different settings and applications. They provide several key benefits that contribute to the overall performance and functionality of trailers:

- 1. Load Handling: Trailer suspensions are designed to support and distribute the weight of various types of cargo. Whether it’s heavy construction materials, fragile goods, or specialized equipment, the suspension system ensures that the trailer can handle the load effectively without compromising stability.

- 2. Terrain Adaptability: Trailer suspensions are engineered to adapt to different terrains, including rough roads, off-road trails, and uneven surfaces. This adaptability allows trailers to navigate challenging environments, making them suitable for construction sites, agricultural fields, and remote areas.

- 3. Smoother Ride: A well-designed suspension system contributes to a smoother and more comfortable ride for both the trailer and its cargo. This is essential for transporting delicate or sensitive goods, as it reduces the risk of damage and ensures a better overall experience for the driver.

- 4. Stability and Control: Suspensions improve the stability and control of trailers, especially when making turns, navigating corners, or driving at high speeds. This enhances safety on the road and minimizes the risk of accidents or rollovers.

- 5. Versatile Attachment Points: Many trailer suspensions feature versatile attachment points that allow for various configurations and types of trailers. This adaptability means that a single suspension system can be used for different trailer designs, providing cost-effective solutions.

- 6. Load Distribution: Trailer suspensions distribute the weight evenly across multiple axles. This even weight distribution prevents excessive strain on individual components and tires, reducing wear and extending the lifespan of the trailer.

- 7. Adjustable Features: Some suspensions come with adjustable features such as airbags or adjustable shock absorbers. These features allow operators to fine-tune the suspension’s performance based on the specific needs of the load and terrain, further enhancing adaptability.

- 8. Maintenance Ease: Properly maintained suspensions are easier to service and repair, making trailers more adaptable in situations where maintenance or repairs are required in remote or challenging locations.

In summary, trailer suspensions are integral to the adaptability and versatility of trailers in various settings. They enable trailers to handle different loads, terrains, and conditions while ensuring safety, stability, and a smoother ride. By selecting the right suspension system and maintaining it effectively, trailer operators can optimize their trailers for a wide range of applications and environments.

Can you explain the primary functions and importance of trailer suspension in towing?

Trailer suspension plays a critical role in towing operations by providing several primary functions and offering overall importance. Here’s a detailed explanation:

- Primary Functions:

- 1. Load Support: One of the primary functions of trailer suspension is to support the weight of the trailer and its cargo. It distributes the weight evenly across the axles, ensuring that no single axle or tire bears an excessive load. This helps prevent overloading, improves stability, and enhances the overall towing experience.

- 2. Shock Absorption: Trailer suspension is responsible for absorbing shocks and vibrations that occur during towing. It consists of various components such as springs, shock absorbers, and airbags that work together to cushion the trailer against road irregularities, bumps, and potholes. By absorbing these shocks, the suspension system reduces the impact transferred to the trailer, providing a smoother and more comfortable ride.

- 3. Stability and Control: Another crucial function of trailer suspension is to maintain stability and control during towing. It helps to keep the trailer level and balanced, preventing excessive swaying, fishtailing, or bouncing. By providing proper weight distribution and managing the trailer’s center of gravity, the suspension system enhances overall stability, making the trailer easier to control and reducing the risk of accidents or loss of control.

- 4. Traction Enhancement: The suspension system contributes to improved traction, especially in challenging road conditions. It helps keep the trailer’s tires in contact with the road surface, maximizing grip and minimizing the chances of slipping or skidding. This is particularly important when towing on uneven or slippery terrains, as the suspension system ensures better traction, enhancing overall safety and maneuverability.

- Importance:

- 1. Safety: Trailer suspension is of utmost importance for towing safety. It helps maintain stability, control, and proper weight distribution, reducing the risk of accidents or loss of control. By absorbing shocks and vibrations, it also minimizes the potential for cargo damage and improves road grip, especially during emergency braking or evasive maneuvers.

- 2. Comfort: A well-designed and properly functioning suspension system enhances the comfort of both the driver and passengers in the towing vehicle. By absorbing road shocks and vibrations, it reduces the jolts, bumps, and vibrations felt inside the vehicle, providing a smoother and more pleasant ride.

- 3. Protection of Cargo: The suspension system helps protect the cargo being transported on the trailer. By absorbing shocks and minimizing vibrations, it reduces the risk of damage to fragile or sensitive cargo. This is particularly important when transporting goods that are susceptible to impact or vibration-related damage.

- 4. Longevity of Trailer Components: Properly functioning trailer suspension reduces the strain on various trailer components, including the frame, axles, tires, and other critical parts. By distributing loads and cushioning impacts, it helps minimize wear and tear, extending the lifespan of these components and reducing the need for repairs or replacements.

In conclusion, trailer suspension serves essential functions in towing operations. It provides load support, absorbs shocks, enhances stability and control, and improves traction. The importance of trailer suspension lies in ensuring towing safety, providing comfort, protecting the cargo, and prolonging the lifespan of trailer components. Regular maintenance and inspection of the suspension system are crucial to ensure its optimal performance and to enjoy a safe and smooth towing experience.

editor by CX 2024-03-23