Product Description

Product Description

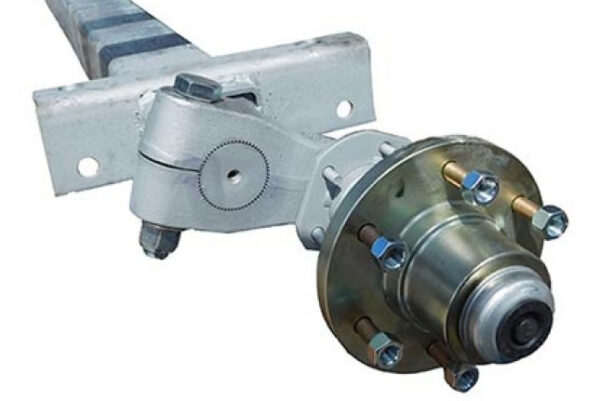

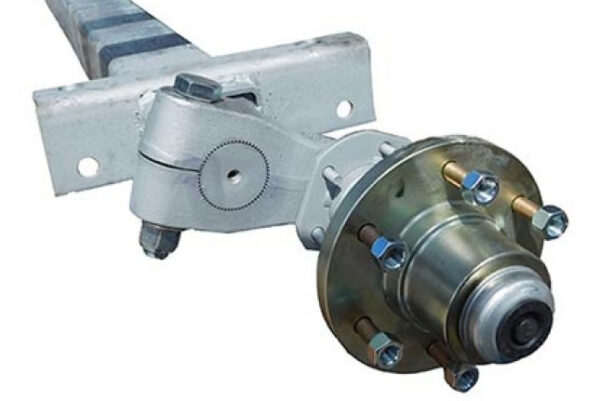

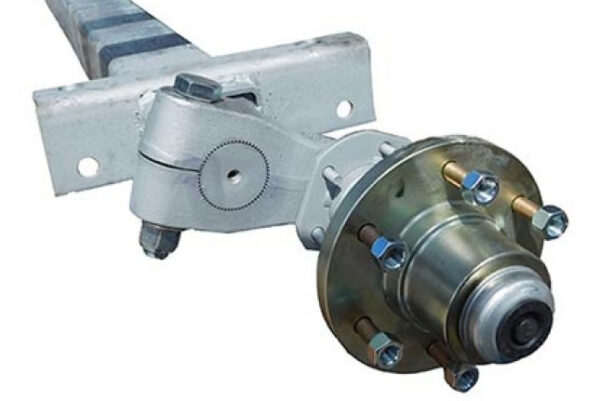

Detailed Photos

Product Parameters

Certifications

Packaging & Shipping

Company Profile

FAQ

1. Q:What’s your best price for this product?

A: We will quote you best price according to your quantity, so when you making an inquiry, please let us know the quantity you want.The more quantity the better price.

2. Q:How about the quality of this product?

A: Our products are certified to ISO9001, TS16949 international quality standards. We compay have very strict Quality Control Systems.

3. Q:What material of the product can you supply?

A: Steel

4. Q:What’s your MOQ?

A: 10pcs for each model. We hope you can buy more to save more money.

5. Q:What’s the delivery time?

A: For products that are in stock, we can ship it within 7 days after receiving your payment. For custom order, quantity within 24 tons, production time is 12-20 days after confirmed every details.

6. Q:What’s your packing?

A:Our usual packing for this product is pallet, we can also supply you packing according to your requirements.

7. Q:Can we custom our own logo or label on this product?

A: Yes, you can. we support logo print & stamping & label print, print will be free if the logo is not very complex.

8. Q:What about the warranty?

A: We are very confident in our products, and we pack them very well to make sure the goods in well protection.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Available |

|---|---|

| Warranty: | One Year |

| Type: | Axle |

| Certification: | ISO/TS16949 |

| Loading Weight: | 25T |

| ABS: | With ABS |

| Samples: |

US$ 25/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do trailer suspensions affect the ride quality and handling of a towing system?

Trailer suspensions have a significant impact on the ride quality and handling of a towing system. Here’s a detailed explanation:

- Ride Quality:

- Shock Absorption: A well-designed suspension system absorbs shocks and vibrations caused by road irregularities, bumps, or potholes. It helps cushion the trailer, providing a smoother and more comfortable ride. Effective shock absorption reduces the jolts and vibrations felt inside the towing vehicle, minimizing driver and passenger discomfort.

- Reduced Bouncing and Pitching: The suspension system plays a crucial role in minimizing excessive bouncing and pitching motions of the trailer. It helps maintain contact between the tires and the road surface, improving stability and reducing the transfer of vertical forces to the towing vehicle. Reduced bouncing and pitching enhance ride comfort and minimize the risk of trailer instability.

- Vertical Movement: A well-calibrated suspension system minimizes excessive vertical movement of the trailer. It helps keep the trailer level and stable, preventing it from bouncing or swaying excessively. This results in a more comfortable and controlled towing experience.

- Handling:

- Stability: A properly designed suspension system enhances the stability of the towing system. It helps distribute the weight evenly across the axles, maintaining proper balance and reducing the risk of swaying or fishtailing. Improved stability contributes to better handling and control, particularly during turns, lane changes, or encounters with crosswinds.

- Steering Response: The suspension system influences the steering response of the towing system. It affects factors such as wheel alignment, tracking, and roll resistance. A well-designed suspension geometry ensures that the wheels track properly, minimizing sideways movement and improving steering precision. This enhances the overall handling and maneuverability of the towing system.

- Trailer Sway Control: The suspension design can incorporate features to mitigate trailer sway. Sway control mechanisms, such as sway bars or electronic stability control systems, can be integrated into the suspension system to improve handling and reduce the risk of trailer sway. These features contribute to safer and more controlled towing.

The suspension system directly influences the ride quality experienced during towing:

The suspension system also affects the handling characteristics of the towing system:

In summary, trailer suspensions significantly affect the ride quality and handling of a towing system. They impact factors such as shock absorption, bouncing and pitching, vertical movement, stability, steering response, and trailer sway control. A well-designed suspension system provides better ride comfort, reduces driver and passenger discomfort, enhances stability, improves handling characteristics, and contributes to a safer and more enjoyable towing experience.

Are there innovations or advancements in trailer suspension technology that have emerged recently?

Yes, there have been notable innovations and advancements in trailer suspension technology in recent years. These innovations aim to improve the performance, durability, and adaptability of trailer suspensions. Here are some of the key advancements:

- 1. Air Ride Suspensions: Air ride suspensions have gained popularity for their ability to provide a smoother ride and better load protection. They use airbags instead of traditional springs, allowing for adjustable levels of cushioning and load support. Some systems even feature automatic load leveling to maintain a consistent ride height.

- 2. Electronic Control Systems: Advanced electronic control systems have been integrated into trailer suspensions. These systems use sensors to monitor road conditions, load weight, and other variables in real-time. They can adjust suspension settings on-the-fly to optimize ride quality, stability, and fuel efficiency.

- 3. Lightweight Materials: Manufacturers are increasingly using lightweight materials such as high-strength alloys and composites to reduce the weight of suspension components. This helps improve fuel efficiency and payload capacity while maintaining structural integrity.

- 4. Predictive Maintenance: Trailer suspension systems are now equipped with predictive maintenance features. These systems monitor wear and tear on components and provide alerts when maintenance is required. This proactive approach reduces downtime and extends the lifespan of the suspension.

- 5. Enhanced Durability: Innovations in materials and design have led to more robust and durable suspension systems. They are better equipped to withstand the rigors of heavy-duty use, including off-road conditions and extreme weather.

- 6. Energy Recovery: Some advanced trailer suspensions incorporate energy recovery systems. These systems capture and store energy generated during the suspension’s movement and can use it to power onboard systems or recharge batteries, improving overall energy efficiency.

- 7. Telematics Integration: Trailer suspension technology is increasingly integrated with telematics systems. This allows for real-time monitoring of suspension performance and the ability to track trailer health remotely, enhancing fleet management and maintenance planning.

These recent advancements in trailer suspension technology contribute to safer, more efficient, and adaptable trailer systems. They benefit a wide range of industries, from logistics and transportation to construction and agriculture, by offering improved ride quality, reduced maintenance costs, and increased overall performance.

What is trailer suspension, and how does it contribute to the smooth operation of a trailer?

Trailer suspension plays a crucial role in the smooth operation of a trailer by providing support, stability, and shock absorption. Here’s a detailed explanation:

- Definition: Trailer suspension refers to the system of components designed to support the trailer’s weight, absorb road shocks, and maintain stability during towing. It typically includes components such as leaf springs, coil springs, torsion axles, airbags, shock absorbers, and linkages that connect the trailer’s axles to the frame.

- Weight Distribution: The primary function of trailer suspension is to distribute the weight of the trailer and its load evenly among the axles. Proper weight distribution is crucial for maintaining stability and preventing excessive strain on individual axles, tires, and other components. A well-designed suspension system ensures that the weight is evenly distributed, reducing the risk of overloading and improving overall towing performance.

- Shock Absorption: Trailer suspension helps absorb road shocks and vibrations, minimizing the impact transferred to the trailer and its cargo. This is achieved through the use of springs and shock absorbers. Springs, such as leaf springs or coil springs, compress and expand to absorb the vertical forces caused by uneven road surfaces, bumps, or potholes. Shock absorbers further dampen these movements, preventing excessive bouncing or jolting and providing a smoother ride.

- Improved Traction and Handling: A well-functioning suspension system enhances traction and handling characteristics of the trailer. By maintaining constant contact between the tires and the road, the suspension system improves traction, especially in challenging road conditions or during maneuvers. It also contributes to better handling, allowing the driver to maintain control over the trailer, reduce sway, and navigate turns more smoothly.

- Reduced Wear and Tear: Trailer suspension helps minimize wear and tear on various components by absorbing and distributing forces. By cushioning the impact of road irregularities, it reduces stress on the trailer’s frame, axles, tires, and other critical parts. This can lead to a longer lifespan of the trailer and its components, reducing the need for repairs or replacements.

- Enhanced Safety: A properly functioning suspension system contributes to the overall safety of towing operations. It helps maintain stability, prevents excessive trailer movement or bouncing, and reduces the risk of losing control or encountering handling issues. By absorbing shocks and vibrations, the suspension system also minimizes the potential for cargo damage and improves road grip, especially in emergency braking situations.

In summary, trailer suspension is a vital component that provides support, stability, and shock absorption in towing applications. It ensures proper weight distribution, absorbs road shocks, improves traction and handling, reduces wear and tear, and enhances overall safety. Regular inspection and maintenance of the trailer suspension system are essential to ensure its optimal performance and contribute to a smooth and trouble-free towing experience.

editor by Dream 2024-05-03

China supplier 6/8/10 Leaf Spring Welding American Type Steel 11ton 13ton 16ton Tandem Axle Truck Mechanic Trailer Suspension

Product Description

6/8/10 Leaf Spring Welding American Type Steel 11ton 13ton 16ton Tandem Axle Truck Mechanic Trailer Suspension

Detailed Photos

We are a factory, manufacturer direct sales, than other companies, our suspension through the truck and trailer strict control, quality is guaranteed.

The front, middle and rear spring hangers are made of high tensile low alloy steel plates (pressed and welded into structure) stronger but lighter than the old type.

A. What are our advantages compared with other Company

- Competive Price – We are Semi Trailers manufacturers/factories.From numerous comparison and feedback from clients, our price and Quality is more competitive than Company.

- Quick Response – Our team is consisted of a group of diligent and enterprising people, working 24/7 to respond client inquiries and questions all the time. Most problems can be solved within 12 hours.

- Fast Delivery – Normally it will take more than 25-45 days for manufacturers/ factories to produce the ordered trailers, while we have a variety of resources, locally and nation widely, to receive trailers in timely manner. In 80% circumstance, we can have a 15-20 days delivery of regular trailers for our clients.

- High Quality – Every process of choose material ,welding ,sand blasting,painting with detailed inspection,accept 100% inspection during production and after production.

B. Which payment terms can we accept?

- Normally we can work on T/T term or L/C term.

- On T/T term, 30% down payment is required in advance, 70% balance shall be settled before delivery, or against the copy of original B/L for regular client.

- On L/C term, normally need 30% down payment by T/T, 70% by L/C at sight. a 100% irrevocable L/C without “soft clauses” can be accepted sometimes. Please seek the advice from the individual sales manager whom you work with.

C. How long will our price be valid?

- Price with long valid time — We are a tender and friendly supplier, never greedy on windfall profit. Basically, our price remains stable through the year. We only adjust our price based on 2 situations: The rate of USD:RMB varies significantly according to the international currency exchange rates. Manufacturers/factories adjusted the trailer price, because of the increasing labor cost and raw material cost.

D. What logistics ways we can work for shipment?

- We can ship all trailer by various transportation tools.

- For 90% of our shipment, we will go by sea, to all main continents such as South America, Middle East, Africa, Oceania etc, either by container or RoRo/Bulk Shipment.

- For neighborhood countries of China, such as Russia, Tajikistan, Kazakhstan,Mongolia etc, we can ship trucks by road or railway.

- For light spare parts in urgent demand, we can ship it by international courier service, such as DHL, TNT, UPS, or Fedex.

CONTACT TO

Clara li

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 24/7 Service for You |

|---|---|

| Warranty: | 1 Year |

| Type: | Suspension |

| Certification: | ISO/TS16949, CCC, ISO |

| Loading Weight: | 13*3 |

| ABS: | Without ABS |

| Samples: |

US$ 180/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do trailer suspensions affect the ride quality and handling of a towing system?

Trailer suspensions have a significant impact on the ride quality and handling of a towing system. Here’s a detailed explanation:

- Ride Quality:

- Shock Absorption: A well-designed suspension system absorbs shocks and vibrations caused by road irregularities, bumps, or potholes. It helps cushion the trailer, providing a smoother and more comfortable ride. Effective shock absorption reduces the jolts and vibrations felt inside the towing vehicle, minimizing driver and passenger discomfort.

- Reduced Bouncing and Pitching: The suspension system plays a crucial role in minimizing excessive bouncing and pitching motions of the trailer. It helps maintain contact between the tires and the road surface, improving stability and reducing the transfer of vertical forces to the towing vehicle. Reduced bouncing and pitching enhance ride comfort and minimize the risk of trailer instability.

- Vertical Movement: A well-calibrated suspension system minimizes excessive vertical movement of the trailer. It helps keep the trailer level and stable, preventing it from bouncing or swaying excessively. This results in a more comfortable and controlled towing experience.

- Handling:

- Stability: A properly designed suspension system enhances the stability of the towing system. It helps distribute the weight evenly across the axles, maintaining proper balance and reducing the risk of swaying or fishtailing. Improved stability contributes to better handling and control, particularly during turns, lane changes, or encounters with crosswinds.

- Steering Response: The suspension system influences the steering response of the towing system. It affects factors such as wheel alignment, tracking, and roll resistance. A well-designed suspension geometry ensures that the wheels track properly, minimizing sideways movement and improving steering precision. This enhances the overall handling and maneuverability of the towing system.

- Trailer Sway Control: The suspension design can incorporate features to mitigate trailer sway. Sway control mechanisms, such as sway bars or electronic stability control systems, can be integrated into the suspension system to improve handling and reduce the risk of trailer sway. These features contribute to safer and more controlled towing.

The suspension system directly influences the ride quality experienced during towing:

The suspension system also affects the handling characteristics of the towing system:

In summary, trailer suspensions significantly affect the ride quality and handling of a towing system. They impact factors such as shock absorption, bouncing and pitching, vertical movement, stability, steering response, and trailer sway control. A well-designed suspension system provides better ride comfort, reduces driver and passenger discomfort, enhances stability, improves handling characteristics, and contributes to a safer and more enjoyable towing experience.

How does the choice of trailer suspensions affect the overall performance and reliability of a trailer?

The choice of trailer suspensions has a significant impact on the overall performance and reliability of a trailer. It influences various aspects of trailer operation and functionality. Here’s how:

- 1. Load Capacity: The type and design of trailer suspensions determine the trailer’s load-carrying capacity. Choosing suspensions with the appropriate load rating ensures that the trailer can safely carry the intended cargo without overloading or straining the suspension components.

- 2. Ride Quality: The choice of suspensions affects the ride quality for both the trailer and the cargo. A well-matched suspension system can provide a smoother and more stable ride, reducing the risk of cargo damage and enhancing driver comfort.

- 3. Handling and Maneuverability: Different suspension systems offer varying levels of handling and maneuverability. Some suspensions are designed for stability during high-speed highway travel, while others excel in off-road or rugged terrain. Choosing the right suspension type ensures optimal handling characteristics.

- 4. Durability and Longevity: The quality and construction of trailer suspensions play a vital role in their durability. High-quality suspensions are less prone to wear and are designed to withstand the rigors of heavy-duty use, resulting in longer service life and increased reliability.

- 5. Maintenance Requirements: The maintenance needs of trailer suspensions can vary depending on their type and design. Some suspensions require more frequent lubrication and inspection, while others are designed for minimal maintenance. Selecting suspensions that align with your maintenance capabilities can affect long-term reliability.

- 6. Adaptability to Terrain: The choice of suspensions impacts the trailer’s adaptability to different terrains. Air suspensions, for example, excel in providing a smooth ride on rough or uneven surfaces, enhancing versatility and reliability in various settings.

- 7. Safety: Properly matched suspensions contribute to trailer safety. A well-balanced suspension system helps prevent trailer sway, reduces the risk of rollovers, and enhances stability during emergency maneuvers, improving overall safety.

- 8. Fuel Efficiency: Some suspensions are designed to minimize rolling resistance, which can improve fuel efficiency. Choosing fuel-efficient suspensions can lead to cost savings over the trailer’s operational lifespan.

- 9. Compatibility with Towing Vehicle: The choice of trailer suspensions should consider the towing vehicle’s specifications. Ensuring compatibility between the trailer suspensions and the towing vehicle’s capabilities is essential for safe and reliable towing.

- 10. Load Distribution: Trailer suspensions play a critical role in distributing the weight of the cargo evenly across the axles. Proper load distribution enhances stability, prevents overloading, and reduces the risk of component wear or failure.

In summary, the choice of trailer suspensions directly impacts the trailer’s performance, reliability, and safety. It’s essential to carefully consider factors such as load capacity, terrain, maintenance requirements, and intended use when selecting suspensions to ensure that they align with the specific needs of your trailer and operational requirements.

What is trailer suspension, and how does it contribute to the smooth operation of a trailer?

Trailer suspension plays a crucial role in the smooth operation of a trailer by providing support, stability, and shock absorption. Here’s a detailed explanation:

- Definition: Trailer suspension refers to the system of components designed to support the trailer’s weight, absorb road shocks, and maintain stability during towing. It typically includes components such as leaf springs, coil springs, torsion axles, airbags, shock absorbers, and linkages that connect the trailer’s axles to the frame.

- Weight Distribution: The primary function of trailer suspension is to distribute the weight of the trailer and its load evenly among the axles. Proper weight distribution is crucial for maintaining stability and preventing excessive strain on individual axles, tires, and other components. A well-designed suspension system ensures that the weight is evenly distributed, reducing the risk of overloading and improving overall towing performance.

- Shock Absorption: Trailer suspension helps absorb road shocks and vibrations, minimizing the impact transferred to the trailer and its cargo. This is achieved through the use of springs and shock absorbers. Springs, such as leaf springs or coil springs, compress and expand to absorb the vertical forces caused by uneven road surfaces, bumps, or potholes. Shock absorbers further dampen these movements, preventing excessive bouncing or jolting and providing a smoother ride.

- Improved Traction and Handling: A well-functioning suspension system enhances traction and handling characteristics of the trailer. By maintaining constant contact between the tires and the road, the suspension system improves traction, especially in challenging road conditions or during maneuvers. It also contributes to better handling, allowing the driver to maintain control over the trailer, reduce sway, and navigate turns more smoothly.

- Reduced Wear and Tear: Trailer suspension helps minimize wear and tear on various components by absorbing and distributing forces. By cushioning the impact of road irregularities, it reduces stress on the trailer’s frame, axles, tires, and other critical parts. This can lead to a longer lifespan of the trailer and its components, reducing the need for repairs or replacements.

- Enhanced Safety: A properly functioning suspension system contributes to the overall safety of towing operations. It helps maintain stability, prevents excessive trailer movement or bouncing, and reduces the risk of losing control or encountering handling issues. By absorbing shocks and vibrations, the suspension system also minimizes the potential for cargo damage and improves road grip, especially in emergency braking situations.

In summary, trailer suspension is a vital component that provides support, stability, and shock absorption in towing applications. It ensures proper weight distribution, absorbs road shocks, improves traction and handling, reduces wear and tear, and enhances overall safety. Regular inspection and maintenance of the trailer suspension system are essential to ensure its optimal performance and contribute to a smooth and trouble-free towing experience.

editor by Dream 2024-05-03

China Professional Hotwork Light Duty Trailer Auto Parts Leaf Spring Suspension

Product Description

The function of vehicle leaf springs:

The leaf spring is composed of many steel plates with elasticity, uniform width and different lengths. Its function is to connect the frame and the axle together in the form of suspension, expose between the frame and the axle, bear the load impact of the wheel on the frame, reduce the violent vibration of the body, maintain the stability of the vehicle and adaptability to different road conditions.

OEM ODM light duty produce Thailand truck parts trailer auto parts leaf spring assy 11436 suspension

Product Parameters

| Delivery time | 7-15 Working days | Payment | T/T, L/C |

| Certificate | CE,ISO | HS Code | 7325712000 |

| Origin | ZheJiang , China | Transport Package | Pallet |

| Material | 65mn, 60si2mn, Sup9, 50crva, 51CRV4 | Type | Truck Leaf Spring |

Company Profile

ZheZheJiang CHINAMFG Auto Parts Co., Ltd. is a modern private enterprise engaged in the design, development and production of automobile leaf spring. The company has been operating for more than 10 years, focusing on the production and development of the existing leaf spring 2 production lines (annual output of more than 30,000 tons).

The company is a domestic supporting enterprise, and has close cooperation with CHINAMFG Xihu (West Lake) Dis. and Sinotruk. Our raw material cooperation manufacturers include HangZhou HangZhou, HangZhou Special Steel, CHINAMFG Special Steel and other large domestic steel mills to ensure the quality of raw materials.

Our production process is all in accordance with the original process, the use of rapid quenching oil for heat treatment, to ensure the level of metallographic structure. Surface shot peening, using stress shot peening machine, effectively ensure residual stress. The paint is treated by electrophoretic spraying, and the salt spray test reaches 400 hours. It has successfully passed various bench and road tests, and can be customized according to the drawings and corresponding requirements.

Company boss Mr. Zhou and technical R & D personnel engaged in more than 20 years, the company independent research and development “filial piety” brand leaf spring, committed to the “good filial piety first, integrity win the world” business philosophy, we do products to “filial piety” as the first person, to “sincere” for the business, welcome friends from all circles to visit and guide.

Main Products:

Benz Series, Single Point Trailer, RV, tractor-trailer, Light Trailer,Faw Xihu (West Lake) Dis. J5, J6 dump truck, tractor full series, J7 tractor series and other leaf springs Heavy auto Haowo, Steyer, T7H, T5H, Shande heavy truck and other dump truck full series leaf springs, Auman, Xihu (West Lake) Dis.feng, ZheJiang auto series leaf springs, Northern Benz series leaf springs, trailer series leaf springs.

FAQ

Q1: What material of the leaf spring can you supply?

A: We can supply different materials of leaf spring, including 60Si2Mn, SUP9,50CrV, 51CrV4, or any material as you require. Before placing the order, please make sure the material to us or we can advise the material to you according to your specification.

Q2: How about the quality of your product?

A: Our products are certified to ISO9001, TS16949 international quality standards. We have very strict Quality Control Systems.

Q3: What’s your best price for your product?

A: We will quote you best price according to your requirements, so when you making an inquiry, please let us know the quantity and material of the product you need. The more quantity, the better price.

Q4:Can we print our own logo or label on the springs?

A: Yes, you can. We support logo print&label print&stamping, normally the print is free.

Q5: What about the package of the product?

A:The goods will be packed according to your requirements and in well protection before delivery.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Provide |

|---|---|

| Warranty: | Provide |

| Type: | Leaf Spring |

| Samples: |

US$ 53/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Please answer in detail: What maintenance practices are recommended for trailer suspensions to ensure optimal functionality?

Proper maintenance of trailer suspensions is crucial to ensure optimal functionality, enhance safety, and extend the lifespan of components. Here are recommended maintenance practices for trailer suspensions:

- 1. Regular Inspections: Conduct routine visual inspections of the entire suspension system, including springs, hangers, bushings, and mounting hardware. Look for signs of wear, corrosion, or damage. Inspect for loose or missing components and address any issues promptly.

- 2. Lubrication: Ensure that all moving parts, such as bushings and pivot points, are adequately lubricated. Lubrication reduces friction, minimizes wear, and promotes smooth movement. Follow the manufacturer’s recommendations for the type and frequency of lubrication.

- 3. Check Spring Alignment: Verify that leaf springs are correctly aligned and not showing signs of misalignment. Misaligned springs can lead to uneven tire wear and affect the stability of the trailer. Correct any misalignments as needed.

- 4. Inspect Shocks and Dampers: Check shock absorbers or dampers for leaks, visible damage, or signs of reduced effectiveness. Worn or damaged shocks can compromise ride quality and handling. Replace shocks that show signs of wear or failure.

- 5. Monitor Air Suspension Systems: If the trailer is equipped with air suspension, regularly inspect airbags, valves, and associated components. Check for leaks, proper inflation, and ensure that air suspension components are in good working condition. Address any air leaks promptly.

- 6. Torque Check for Fasteners: Periodically check and torque all fasteners, including bolts, nuts, and U-bolts. Loose or improperly tightened fasteners can lead to component failure and compromise the integrity of the suspension system.

- 7. Check Suspension Alignment: Verify that the suspension components are properly aligned. Misaligned components can cause uneven tire wear and affect the handling of the trailer. Correct any alignment issues to ensure even weight distribution.

- 8. Inspect Bushings and Wear Points: Check for wear on bushings and other wear points in the suspension system. Excessive wear can lead to play in the components and affect the trailer’s stability. Replace worn bushings and components as part of routine maintenance.

- 9. Examine Brake Components: Inspect brake components, including drums, pads, and calipers. Ensure that the brakes are functioning correctly and that there is even wear on the brake components. Replace any worn or damaged brake parts promptly.

- 10. Perform Wheel Alignment: Maintain proper wheel alignment to prevent irregular tire wear and ensure straight-line stability. Misaligned wheels can place additional stress on suspension components and lead to premature wear.

- 11. Address Unusual Noises: Pay attention to any unusual noises coming from the suspension during operation. Clunks, squeaks, or rattles may indicate underlying issues. Investigate and address the source of unusual noises promptly.

- 12. Follow Manufacturer Recommendations: Adhere to the manufacturer’s recommended maintenance schedule and guidelines. Manufacturers provide specific instructions for maintaining their suspension systems, and following these recommendations is essential for optimal performance and warranty compliance.

- 13. Consider Professional Inspections: Periodically, consider having the trailer suspension system professionally inspected. Trained technicians can identify potential issues that may not be visible during routine inspections, ensuring comprehensive maintenance.

By incorporating these maintenance practices into a routine schedule, trailer owners and operators can help ensure that the suspension system operates optimally, promoting safety, reliability, and longevity.

What safety considerations should be taken into account when using trailer suspensions in towing?

When using trailer suspensions in towing, it’s crucial to prioritize safety to prevent accidents and ensure the well-being of both the driver and other road users. Here are important safety considerations to keep in mind:

- 1. Weight Distribution: Properly distribute the weight of the cargo within the trailer. Ensure that the load is evenly balanced to prevent overloading of one axle or side, which can lead to instability and loss of control.

- 2. Load Capacity: Stay within the specified load capacity of the trailer suspension. Overloading can strain the suspension components, leading to premature wear and potential failure.

- 3. Regular Inspections: Conduct routine inspections of the trailer suspension system, including springs, shocks, and fasteners. Look for signs of wear, damage, or loose components. Address any issues promptly to prevent accidents.

- 4. Tire Maintenance: Ensure that trailer tires are in good condition, properly inflated, and have adequate tread depth. Bald or underinflated tires can lead to blowouts or loss of control during towing.

- 5. Brake System: Maintain the trailer’s brake system in optimal condition. Test and adjust the brakes as needed to ensure they provide effective stopping power. Inadequate brakes can result in longer stopping distances and accidents.

- 6. Trailer Lights: Ensure that all trailer lights, including brake lights, turn signals, and taillights, are functioning correctly. Proper lighting enhances visibility and signals your intentions to other drivers.

- 7. Trailer Hitch: Use a compatible and properly installed trailer hitch that is rated for the weight of your trailer and load. Make sure the hitch is securely attached to the towing vehicle and the trailer tongue.

- 8. Secure Cargo: Secure the cargo inside the trailer to prevent shifting during transit. Use appropriate tie-downs and restraints to keep the load stable and prevent accidents caused by cargo movement.

- 9. Driving Speed: Adhere to safe driving speeds and follow posted speed limits. Speeding while towing can reduce your ability to react to unexpected situations and increase the risk of accidents.

- 10. Towing Vehicle: Ensure that the towing vehicle is in good mechanical condition. Regularly service the vehicle’s engine, brakes, transmission, and suspension to maintain towing performance and safety.

- 11. Emergency Equipment: Carry essential emergency equipment, including a jack, spare tire, fire extinguisher, first aid kit, and reflective warning triangles. These items can be invaluable in case of roadside emergencies.

- 12. Weather Conditions: Adjust your driving behavior and maintain a safe following distance in adverse weather conditions, such as rain, snow, or ice. Wet or slippery roads can increase stopping distances and reduce traction.

- 13. Driver Training: Ensure that the driver has the necessary training and experience in towing trailers. Towing a trailer requires specific skills and awareness of handling differences compared to driving without a trailer.

- 14. Emergency Procedures: Familiarize yourself with emergency procedures, including how to react in the event of trailer sway, jackknifing, or other critical situations. Knowing how to respond can prevent accidents from escalating.

Prioritizing safety when using trailer suspensions in towing is essential for preventing accidents and ensuring a secure and efficient towing experience. Regular maintenance, proper load management, and adherence to safety guidelines are key to safe towing operations.

What are the different types and configurations of trailer suspensions available in the market?

There are several different types and configurations of trailer suspensions available in the market. Here’s a detailed explanation:

- Leaf Spring Suspension:

- Coil Spring Suspension:

- Torsion Axle Suspension:

- Air Suspension:

- Independent Suspension:

- Rubber Torsion Suspension:

Leaf spring suspension is one of the most common types of suspensions used in trailers. It consists of multiple layers of curved metal strips (leaves) that flex and absorb shocks. Leaf springs are durable, cost-effective, and provide good load-carrying capacity. They are typically arranged in a single or dual configuration, where two leaf springs are mounted parallel to each other on each side of the trailer.

Coil spring suspension utilizes helical coil springs to provide support and shock absorption. This type of suspension offers a smoother ride and improved comfort compared to leaf spring suspensions. Coil springs can be mounted in various configurations, including single or dual setups, depending on the trailer’s weight and load requirements.

Torsion axle suspension is a type of independent suspension commonly used in trailers. It consists of rubberized torsion arms that provide suspension for each wheel independently. Torsion axle suspensions offer excellent shock absorption, improved stability, and a smoother ride. They are often used in utility trailers, RVs, and other applications that require enhanced towing comfort.

Air suspension systems utilize airbags or air springs to support the trailer’s weight and provide adjustable suspension stiffness. These suspensions offer a high level of adjustability, allowing the user to modify the ride height and stiffness according to the load requirements. Air suspensions provide excellent load leveling, improved ride quality, and are commonly used in heavy-duty trailers or specialized applications.

Independent suspension systems allow each wheel to move independently of the others. This type of suspension provides superior shock absorption, stability, and improved handling characteristics. Independent suspensions are often found in high-end trailers, including luxury RVs or high-performance trailers.

Rubber torsion suspension is a type of suspension that uses rubber cords or rods instead of traditional springs. The rubber cords provide the necessary support and shock absorption, eliminating the need for separate springs. Rubber torsion suspensions offer a smooth and quiet ride, reduced maintenance, and are commonly used in smaller trailers, such as boat trailers or utility trailers.

In summary, the market offers a range of trailer suspensions, including leaf spring, coil spring, torsion axle, air suspension, independent suspension, and rubber torsion suspension. Each type of suspension has its own advantages and is suitable for different trailer applications based on factors such as load requirements, ride comfort, stability, and adjustability.

editor by Dream 2024-05-03

China best Semi Trailer Bogie Axle Suspension

Product Description

Product Description

High quality Single point suspension semi trailer bogie axle suspension

| Model | FSHS24GNS1 | FSHS24GNS2 | FSHS28GNS1 | FSHS28GNS2 | FSHS32GNS1 | FSHS32GNS2 | FSHS36GNS1 | FSHS36GNS2 |

| Rated loading capacity (kg) | 24000 | 24000 | 28000 | 28000 | 32000 | 32000 | 36000 | 36000 |

| Spring center distance (mm) | 980 | 980 | 900 | 900 | 900 | 900 | 900 | 900 |

| Height of pedestal center (mm) | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 |

| Axle distance (mm) | 1400 | 1400 | 1550 | 1550 | 1550 | 1550 | 1550 | 1550 |

| Axle model | FSA12GNS3 | FSA12GFS1 | FSA14GNS4 | FSA14GFS1 | FSA16GNS2 | FSA16GFS1 | FSA18GNS1 | FSA18GNS1 |

| Wheel track (mm) | 1840 | 1870 | 1850 | 1840 | 1840 | 1850 | 1850 | 1870 |

| Recommended wheel | 7.50V-20 | 8.50V-24 | 8.00V-20 | 8.50V-24 | 8.50V-20 | 8.50V-24 | 8.50V-20 | 8.50V-24 |

| Weight(kg) | 1900 | 2015 | 2308 | 2438 | 2385 | 2465 | 2456 | 2470 |

Our factory

Loading

Fair&Certifictae

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Semi-Trailer |

|---|---|

| Load Capacity: | 24 28 32 36ton |

| Certification: | ECE, GCC, CE, ISO9001, DOT, CCC, ISO/TS16949 |

| Grade: | Heavy Duty |

| Types of Suspension Systems: | 32 Ton Bogie Suspension with Spoke Axles |

| Tire Number: | 6 |

| Customization: |

Available

|

|

|---|

Can you provide examples of trailers or towing applications that commonly use suspensions?

Yes, various trailers and towing applications commonly use suspensions to ensure optimal performance, stability, and ride comfort. Here are some examples:

- Utility Trailers:

- Recreational Trailers:

- Horse Trailers:

- Boat Trailers:

- Commercial Trailers:

Utility trailers, including flatbed trailers, enclosed trailers, and landscape trailers, often utilize suspensions. These trailers are used for a wide range of purposes such as transporting equipment, materials, or goods. Suspensions help provide a smoother ride and improved load-carrying capacity, ensuring that the trailer can handle different types of cargo and road conditions.

Recreational trailers, such as travel trailers, fifth-wheel trailers, and toy haulers, commonly incorporate suspensions. These trailers are designed for recreational purposes, including camping, road trips, and outdoor adventures. The suspensions help enhance ride comfort, stability, and handling characteristics, providing a more enjoyable towing experience for the occupants.

Horse trailers, which are specifically designed to transport horses, often utilize suspensions. These trailers typically have special features such as dividers, ramps, and ventilation systems to ensure the safety and well-being of the horses during transportation. Suspensions play a crucial role in minimizing vibrations and shocks, providing a smoother ride for the horses and reducing their stress levels.

Boat trailers are used to transport boats from one location to another, such as from a storage facility to a launch site. These trailers need to accommodate the weight and dimensions of the boat while providing stability and maneuverability on the road. Suspensions help absorb shocks and vibrations, preventing damage to the boat and ensuring a smoother towing experience.

Various types of commercial trailers, including semi-trailers, refrigerated trailers, and tanker trailers, rely on suspensions. These trailers are used in industries such as logistics, transportation, and bulk liquid hauling. Suspensions are essential to handle heavy loads, maintain stability, and ensure safe and efficient transportation of goods over long distances.

These are just a few examples, and suspensions are utilized in a wide range of other trailer types and towing applications as well. It’s important for trailer owners and operators to select the appropriate suspension system based on the specific requirements of their trailers, including load capacity, intended use, road conditions, and regulations.

In summary, suspensions are commonly used in utility trailers, recreational trailers, horse trailers, boat trailers, commercial trailers, and many other types of trailers and towing applications. The inclusion of suspensions helps improve ride quality, stability, and handling characteristics, ensuring a safe and comfortable towing experience.

How does the choice of trailer suspensions affect the overall performance and reliability of a trailer?

The choice of trailer suspensions has a significant impact on the overall performance and reliability of a trailer. It influences various aspects of trailer operation and functionality. Here’s how:

- 1. Load Capacity: The type and design of trailer suspensions determine the trailer’s load-carrying capacity. Choosing suspensions with the appropriate load rating ensures that the trailer can safely carry the intended cargo without overloading or straining the suspension components.

- 2. Ride Quality: The choice of suspensions affects the ride quality for both the trailer and the cargo. A well-matched suspension system can provide a smoother and more stable ride, reducing the risk of cargo damage and enhancing driver comfort.

- 3. Handling and Maneuverability: Different suspension systems offer varying levels of handling and maneuverability. Some suspensions are designed for stability during high-speed highway travel, while others excel in off-road or rugged terrain. Choosing the right suspension type ensures optimal handling characteristics.

- 4. Durability and Longevity: The quality and construction of trailer suspensions play a vital role in their durability. High-quality suspensions are less prone to wear and are designed to withstand the rigors of heavy-duty use, resulting in longer service life and increased reliability.

- 5. Maintenance Requirements: The maintenance needs of trailer suspensions can vary depending on their type and design. Some suspensions require more frequent lubrication and inspection, while others are designed for minimal maintenance. Selecting suspensions that align with your maintenance capabilities can affect long-term reliability.

- 6. Adaptability to Terrain: The choice of suspensions impacts the trailer’s adaptability to different terrains. Air suspensions, for example, excel in providing a smooth ride on rough or uneven surfaces, enhancing versatility and reliability in various settings.

- 7. Safety: Properly matched suspensions contribute to trailer safety. A well-balanced suspension system helps prevent trailer sway, reduces the risk of rollovers, and enhances stability during emergency maneuvers, improving overall safety.

- 8. Fuel Efficiency: Some suspensions are designed to minimize rolling resistance, which can improve fuel efficiency. Choosing fuel-efficient suspensions can lead to cost savings over the trailer’s operational lifespan.

- 9. Compatibility with Towing Vehicle: The choice of trailer suspensions should consider the towing vehicle’s specifications. Ensuring compatibility between the trailer suspensions and the towing vehicle’s capabilities is essential for safe and reliable towing.

- 10. Load Distribution: Trailer suspensions play a critical role in distributing the weight of the cargo evenly across the axles. Proper load distribution enhances stability, prevents overloading, and reduces the risk of component wear or failure.

In summary, the choice of trailer suspensions directly impacts the trailer’s performance, reliability, and safety. It’s essential to carefully consider factors such as load capacity, terrain, maintenance requirements, and intended use when selecting suspensions to ensure that they align with the specific needs of your trailer and operational requirements.

Can you describe the factors to consider when selecting trailer suspensions for specific applications?

When selecting trailer suspensions for specific applications, several factors need to be considered. Here’s a detailed explanation:

- Load Capacity:

- Towing Conditions:

- Trailer Type:

- Comfort:

- Budget:

- Maintenance and Durability:

- Special Requirements:

The load capacity of the trailer suspension is a crucial factor to consider. It should be able to handle the anticipated weight of the trailer’s cargo. The suspension system should have sufficient load-carrying capacity to support the payload and distribute the weight evenly across the axles.

The towing conditions play a significant role in determining the appropriate trailer suspension. Consider factors such as the type of terrain, road conditions, and towing speed. For example, if the trailer will be frequently used on rough or uneven roads, a suspension system with excellent shock absorption capabilities, such as an independent suspension or air suspension, may be preferred.

The type of trailer being used is an essential consideration. Different trailers have varying requirements based on their intended purpose. For instance, utility trailers carrying heavy equipment may benefit from leaf spring suspensions due to their load-carrying capacity, while enclosed trailers transporting delicate cargo may require suspensions that provide superior shock absorption and stability.

If towing comfort is a priority, the suspension system’s ability to provide a smooth and stable ride becomes crucial. Factors such as shock absorption, vibration dampening, and reduced trailer sway contribute to a comfortable towing experience. Suspensions like torsion axle suspensions or air suspensions are often chosen for their superior ride quality.

The budget available for the trailer suspension is an important factor to consider. Different suspension systems have varying costs associated with their design, construction, and components. It’s important to balance the desired features and performance with the available budget.

The maintenance requirements and durability of the suspension system should be evaluated. Some suspensions may require more frequent maintenance, such as lubrication or component replacements, while others may offer longer service intervals. It’s important to consider the expected lifespan of the suspension and the associated maintenance costs.

Specific applications may have unique requirements that need to be taken into account. For example, trailers used for hauling livestock may require suspensions that minimize stress and vibrations to ensure the well-being of the animals. Specialized trailers, such as boat trailers, may need suspensions that offer protection against water or corrosion.

In summary, when selecting trailer suspensions for specific applications, factors such as load capacity, towing conditions, trailer type, comfort, budget, maintenance, durability, and any special requirements should be carefully considered. Evaluating these factors will help determine the most suitable suspension system that can provide optimal performance, stability, and comfort for the intended application.

editor by Dream 2024-05-03

China best Trailer Suspension System Trailer Suspension for Heavy Duty Container Trailers Hot Selling

Product Description

Product Specification

| Suspension with axle together | |||||||

| Height of towing plate | Suspension | Leaf spring | Leaf spring width | Balance arm pin | Hangers | Eqoalizer | |

| 1180mm | 1210mm | 3 axle suspension | 8 leaf | 90mm | 50 | material Q235 | thickness |

| 1230mm | 1250mm | 9 leaf | 100mm | 60 | thickness | 8mm | |

| 1300mm | the quantity is optional | 120mm | 70 | 8mm | 10mm | ||

| 10mm | |||||||

| We can produce according to your samples,drawings | |||||||

Product Display

Related Products

Packaging and Transportation

Customer Photo

Our Certificate

Company Profile

FAQ:

1. Can you produce or modify the products we want?

Samples for development are warmly welcomed. We have rich experience in developing

and modifying it.

2. I could not meet your MOQ/I want to try your products in a small quantity before

bulk orders.

Sample test and sample orders could be accepted if we have in stock.

3. What’s your payment terms?

LC,TT, Western Union.

4. What’s the process of placing orders?

Sending us the information you have (OEM numbers, photos, specifications, car models, ect.)

We quote and send you photos and other details for confirmation.

Discussing about all details you want to know (packing, delivery terms,warranty, ect. )

You can add our WhatsApp.

Order process will be informed by emails from time to time.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Stainless Steel |

|---|---|

| Certification: | ISO/TS16949, ISO9001 |

| Position: | Rear |

| OEM: | Yes |

| Type: | Suspension Spring |

| Towing Plate: | 1180mm, 1210mm, 1230mm, 1250, 1300mm |

| Customization: |

Available

|

|

|---|

Can trailer suspensions be customized for specific trailer types or load capacities?

Yes, trailer suspensions can be customized to accommodate specific trailer types or load capacities. Here’s a detailed explanation:

Trailer suspensions are available in various configurations, and manufacturers often provide options that can be tailored to meet specific requirements. Customization allows trailer owners to select suspensions that are best suited for their particular trailer type and intended use.

Here are some ways in which trailer suspensions can be customized:

- Load Capacity: Trailer suspensions can be designed and rated to handle different load capacities. The suspension components, such as springs, axles, and shock absorbers, can be specified to match the anticipated weight of the trailer’s cargo. This ensures that the suspension system provides adequate support and maintains proper ride height under the expected load.

- Suspension Type: Different types of suspensions are available, and the choice depends on the specific trailer type and requirements. For example, leaf spring suspensions are commonly used for their durability and load-carrying capacity, while torsion axle suspensions provide excellent shock absorption and improved ride quality. By selecting the appropriate suspension type, trailer owners can optimize the performance and characteristics of their trailers.

- Configuration and Geometry: Trailer suspensions can be customized in terms of their configuration and geometry. This includes the number and arrangement of springs, the placement of axles, and the overall design of the suspension system. For instance, trailers carrying heavy loads may benefit from a dual-axle configuration for better weight distribution and increased stability.

- Adjustability: Some trailer suspensions offer adjustability features that allow fine-tuning based on specific needs. For example, air suspensions provide adjustable ride height and stiffness, allowing users to adapt the suspension to different load conditions. This adjustability enhances versatility and performance.

- Specialized Requirements: In certain cases, trailer suspensions may need to be customized to meet specialized requirements. This could include factors such as off-road capabilities, specific industry standards, or unique environmental conditions. Manufacturers can work with trailer owners to design and build suspensions that meet these specific needs.

It’s important to note that customization options may vary depending on the manufacturer and the specific suspension system. Working with reputable trailer manufacturers or suspension specialists can help ensure that the customization is done correctly and in accordance with industry standards.

In summary, trailer suspensions can be customized to match specific trailer types or load capacities. By selecting the appropriate suspension components, type, configuration, adjustability options, and addressing specialized requirements, trailer owners can optimize the performance, safety, and overall functionality of their trailers.

How does the choice of trailer suspensions affect the overall performance and reliability of a trailer?

The choice of trailer suspensions has a significant impact on the overall performance and reliability of a trailer. It influences various aspects of trailer operation and functionality. Here’s how:

- 1. Load Capacity: The type and design of trailer suspensions determine the trailer’s load-carrying capacity. Choosing suspensions with the appropriate load rating ensures that the trailer can safely carry the intended cargo without overloading or straining the suspension components.

- 2. Ride Quality: The choice of suspensions affects the ride quality for both the trailer and the cargo. A well-matched suspension system can provide a smoother and more stable ride, reducing the risk of cargo damage and enhancing driver comfort.

- 3. Handling and Maneuverability: Different suspension systems offer varying levels of handling and maneuverability. Some suspensions are designed for stability during high-speed highway travel, while others excel in off-road or rugged terrain. Choosing the right suspension type ensures optimal handling characteristics.

- 4. Durability and Longevity: The quality and construction of trailer suspensions play a vital role in their durability. High-quality suspensions are less prone to wear and are designed to withstand the rigors of heavy-duty use, resulting in longer service life and increased reliability.

- 5. Maintenance Requirements: The maintenance needs of trailer suspensions can vary depending on their type and design. Some suspensions require more frequent lubrication and inspection, while others are designed for minimal maintenance. Selecting suspensions that align with your maintenance capabilities can affect long-term reliability.

- 6. Adaptability to Terrain: The choice of suspensions impacts the trailer’s adaptability to different terrains. Air suspensions, for example, excel in providing a smooth ride on rough or uneven surfaces, enhancing versatility and reliability in various settings.

- 7. Safety: Properly matched suspensions contribute to trailer safety. A well-balanced suspension system helps prevent trailer sway, reduces the risk of rollovers, and enhances stability during emergency maneuvers, improving overall safety.

- 8. Fuel Efficiency: Some suspensions are designed to minimize rolling resistance, which can improve fuel efficiency. Choosing fuel-efficient suspensions can lead to cost savings over the trailer’s operational lifespan.

- 9. Compatibility with Towing Vehicle: The choice of trailer suspensions should consider the towing vehicle’s specifications. Ensuring compatibility between the trailer suspensions and the towing vehicle’s capabilities is essential for safe and reliable towing.

- 10. Load Distribution: Trailer suspensions play a critical role in distributing the weight of the cargo evenly across the axles. Proper load distribution enhances stability, prevents overloading, and reduces the risk of component wear or failure.

In summary, the choice of trailer suspensions directly impacts the trailer’s performance, reliability, and safety. It’s essential to carefully consider factors such as load capacity, terrain, maintenance requirements, and intended use when selecting suspensions to ensure that they align with the specific needs of your trailer and operational requirements.

In what types of trailers are suspensions commonly used, and how do they vary?

Suspensions are commonly used in various types of trailers to provide support, stability, and shock absorption. Here’s a detailed explanation:

- Types of Trailers:

- 1. Utility Trailers: Utility trailers, including flatbed trailers, equipment trailers, and landscape trailers, often feature suspensions. These trailers are designed to transport a wide range of materials, equipment, or goods and require suspensions to ensure load support, stability, and a smoother ride.

- 2. Enclosed Trailers: Enclosed trailers, such as cargo trailers and box trailers, are commonly equipped with suspensions. These trailers are used for transporting goods that require protection from the elements and benefit from suspensions to absorb shocks, enhance stability, and protect the cargo.

- 3. Livestock Trailers: Livestock trailers, used for transporting animals, typically have suspensions to provide a smoother ride and minimize stress on the animals. The suspensions help absorb shocks and vibrations, ensuring the well-being and safety of the livestock during transportation.

- 4. RV Trailers: Recreational vehicles (RVs), including travel trailers and fifth-wheel trailers, utilize suspensions to enhance comfort and stability. These trailers are designed for living and leisure purposes and benefit from suspensions to provide a smoother ride, reduce vibrations, and improve overall towing experience.

- 5. Boat Trailers: Boat trailers, used for transporting boats to and from the water, often feature suspensions. These suspensions help absorb road shocks and vibrations, ensuring the safety of the boat during transportation and minimizing potential damage to the hull and other components.

- Variations in Suspensions:

- 1. Leaf Spring Suspension: Leaf spring suspensions are widely used in trailers and consist of multiple layers of curved metal strips (leaves) that flex and absorb shocks. They are known for their durability, load-carrying capacity, and cost-effectiveness.

- 2. Coil Spring Suspension: Coil spring suspensions use helical coil springs to provide support and shock absorption. They offer a smoother ride and are commonly used in trailers that require improved comfort, such as RVs or enclosed trailers.

- 3. Torsion Axle Suspension: Torsion axle suspensions use a rubberized torsion arm system to provide independent suspension for each wheel. They offer excellent shock absorption, improved stability, and are commonly used in utility trailers and RVs.

- 4. Air Suspension: Air suspensions utilize airbags to support the trailer’s weight and provide adjustable suspension stiffness. They offer a high level of adjustability, enhanced ride quality, and are commonly used in heavy-duty trailers or specialized applications.

- 5. Independent Suspension: Independent suspensions allow each wheel to move independently, providing superior shock absorption and stability. They are commonly used in high-end trailers, including luxury RVs or high-performance trailers.

Suspensions are commonly found in the following types of trailers:

Suspensions used in trailers can vary based on their design, construction, and intended use. Here are some common variations:

In summary, suspensions are commonly used in utility trailers, enclosed trailers, livestock trailers, RV trailers, and boat trailers. The choice of suspension varies based on trailer type and requirements. Common variations include leaf spring suspension, coil spring suspension, torsion axle suspension, air suspension, and independent suspension. Each type offers specific benefits in terms of load support, shock absorption, stability, and ride quality, catering to the diverse needs of different trailer applications.

editor by Dream 2024-05-02

China Best Sales New Truck Trailer Steel Leaf Spring Semi Truck Suspension

Product Description

Quick details:

| Place of Origin | HangZhou China |

| Brand Name | Xiaocheng |

| Material | 65Mn, 60Si2Mn, Sup9, 50crva, 51CRV4 ,55CrMnA,Alloy,Or As you required |

| Model Number | Leaf Spring |

| Certificate | TS16949,ISO,CE |

| Application | commercial vehicles |

| Weight | 20-100kgs |

| Breadth | 76,90,100,120mmthickness |

| Thickness | 10,11,12,13,14,16,18,20,38mm,etc. |

| Packing | Export Standard Packing by Pallet |

| Size | customized |

Product Description

Detailed Photos

Packaging & Shipping

Company Profile

ZheZheJiang CHINAMFG Auto Parts Co., Ltd. is a modern private enterprise engaged in the design, development and production of automobile leaf spring. The company has been operating for more than 10 years, focusing on the production and development of the existing leaf spring 2 production lines (annual output of more than 30,000 tons).

The company is a domestic supporting enterprise, and has close cooperation with CHINAMFG Xihu (West Lake) Dis. and Sinotruk. Our raw material cooperation manufacturers include HangZhou HangZhou, HangZhou Special Steel, CHINAMFG Special Steel and other large domestic steel mills to ensure the quality of raw materials.

Our production process is all in accordance with the original process, the use of rapid quenching oil for heat treatment, to ensure the level of metallographic structure. Surface shot peening, using stress shot peening machine, effectively ensure residual stress. The paint is treated by electrophoretic spraying, and the salt spray test reaches 400 hours. It has successfully passed various bench and road tests, and can be customized according to the drawings and corresponding requirements.

Company boss Mr. Zhou and technical R & D personnel engaged in more than 20 years, the company independent research and development “filial piety” brand leaf spring, committed to the “good filial piety first, integrity win the world” business philosophy, we do products to “filial piety” as the first person, to “sincere” for the business, welcome friends from all circles to visit and guide.

Main Products:

Benz Series, Single Point Trailer, RV, tractor-trailer, Light Trailer,Faw Xihu (West Lake) Dis. J5, J6 dump truck, tractor full series, J7 tractor series and other leaf springs Heavy auto Haowo, Steyer, T7H, T5H, Shande heavy truck and other dump truck full series leaf springs, Auman, Xihu (West Lake) Dis.feng, ZheJiang auto series leaf springs, Northern Benz series leaf springs, trailer series leaf springs.

Our Advantages

FAQ

Q1: What material of the leaf spring can you supply?

A: We can supply different materials of leaf spring, including 60Si2Mn, SUP9,50CrV, 51CrV4, or any material as you require. Before placing the order, please make sure the material to us or we can advise the material to you according to your specification.

Q2: How about the quality of your product?

A: Our products are certified to ISO9001, TS16949 international quality standards. We have very strict Quality Control Systems.

Q3: What’s your best price for your product?

A: We will quote you best price according to your requirements, so when you making an inquiry, please let us know the quantity and material of the product you need. The more quantity, the better price.

Q4:Can we print our own logo or label on the springs?

A: Yes, you can. We support logo print&label print&stamping, normally the print is free.

Q5: What about the package of the product?

A:The goods will be packed according to your requirements and in well protection before delivery.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Provide |

|---|---|

| Warranty: | Provide |

| Material: | Carbon Steel |

| Samples: |

US$ 58/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do trailer suspensions affect the ride quality and handling of a towing system?

Trailer suspensions have a significant impact on the ride quality and handling of a towing system. Here’s a detailed explanation:

- Ride Quality:

- Shock Absorption: A well-designed suspension system absorbs shocks and vibrations caused by road irregularities, bumps, or potholes. It helps cushion the trailer, providing a smoother and more comfortable ride. Effective shock absorption reduces the jolts and vibrations felt inside the towing vehicle, minimizing driver and passenger discomfort.

- Reduced Bouncing and Pitching: The suspension system plays a crucial role in minimizing excessive bouncing and pitching motions of the trailer. It helps maintain contact between the tires and the road surface, improving stability and reducing the transfer of vertical forces to the towing vehicle. Reduced bouncing and pitching enhance ride comfort and minimize the risk of trailer instability.

- Vertical Movement: A well-calibrated suspension system minimizes excessive vertical movement of the trailer. It helps keep the trailer level and stable, preventing it from bouncing or swaying excessively. This results in a more comfortable and controlled towing experience.

- Handling:

- Stability: A properly designed suspension system enhances the stability of the towing system. It helps distribute the weight evenly across the axles, maintaining proper balance and reducing the risk of swaying or fishtailing. Improved stability contributes to better handling and control, particularly during turns, lane changes, or encounters with crosswinds.

- Steering Response: The suspension system influences the steering response of the towing system. It affects factors such as wheel alignment, tracking, and roll resistance. A well-designed suspension geometry ensures that the wheels track properly, minimizing sideways movement and improving steering precision. This enhances the overall handling and maneuverability of the towing system.

- Trailer Sway Control: The suspension design can incorporate features to mitigate trailer sway. Sway control mechanisms, such as sway bars or electronic stability control systems, can be integrated into the suspension system to improve handling and reduce the risk of trailer sway. These features contribute to safer and more controlled towing.

The suspension system directly influences the ride quality experienced during towing:

The suspension system also affects the handling characteristics of the towing system:

In summary, trailer suspensions significantly affect the ride quality and handling of a towing system. They impact factors such as shock absorption, bouncing and pitching, vertical movement, stability, steering response, and trailer sway control. A well-designed suspension system provides better ride comfort, reduces driver and passenger discomfort, enhances stability, improves handling characteristics, and contributes to a safer and more enjoyable towing experience.

How does the choice of trailer suspensions affect the overall performance and reliability of a trailer?

The choice of trailer suspensions has a significant impact on the overall performance and reliability of a trailer. It influences various aspects of trailer operation and functionality. Here’s how:

- 1. Load Capacity: The type and design of trailer suspensions determine the trailer’s load-carrying capacity. Choosing suspensions with the appropriate load rating ensures that the trailer can safely carry the intended cargo without overloading or straining the suspension components.

- 2. Ride Quality: The choice of suspensions affects the ride quality for both the trailer and the cargo. A well-matched suspension system can provide a smoother and more stable ride, reducing the risk of cargo damage and enhancing driver comfort.

- 3. Handling and Maneuverability: Different suspension systems offer varying levels of handling and maneuverability. Some suspensions are designed for stability during high-speed highway travel, while others excel in off-road or rugged terrain. Choosing the right suspension type ensures optimal handling characteristics.

- 4. Durability and Longevity: The quality and construction of trailer suspensions play a vital role in their durability. High-quality suspensions are less prone to wear and are designed to withstand the rigors of heavy-duty use, resulting in longer service life and increased reliability.

- 5. Maintenance Requirements: The maintenance needs of trailer suspensions can vary depending on their type and design. Some suspensions require more frequent lubrication and inspection, while others are designed for minimal maintenance. Selecting suspensions that align with your maintenance capabilities can affect long-term reliability.

- 6. Adaptability to Terrain: The choice of suspensions impacts the trailer’s adaptability to different terrains. Air suspensions, for example, excel in providing a smooth ride on rough or uneven surfaces, enhancing versatility and reliability in various settings.

- 7. Safety: Properly matched suspensions contribute to trailer safety. A well-balanced suspension system helps prevent trailer sway, reduces the risk of rollovers, and enhances stability during emergency maneuvers, improving overall safety.

- 8. Fuel Efficiency: Some suspensions are designed to minimize rolling resistance, which can improve fuel efficiency. Choosing fuel-efficient suspensions can lead to cost savings over the trailer’s operational lifespan.

- 9. Compatibility with Towing Vehicle: The choice of trailer suspensions should consider the towing vehicle’s specifications. Ensuring compatibility between the trailer suspensions and the towing vehicle’s capabilities is essential for safe and reliable towing.

- 10. Load Distribution: Trailer suspensions play a critical role in distributing the weight of the cargo evenly across the axles. Proper load distribution enhances stability, prevents overloading, and reduces the risk of component wear or failure.

In summary, the choice of trailer suspensions directly impacts the trailer’s performance, reliability, and safety. It’s essential to carefully consider factors such as load capacity, terrain, maintenance requirements, and intended use when selecting suspensions to ensure that they align with the specific needs of your trailer and operational requirements.

How does the design of a trailer suspension impact the overall stability and comfort during towing?

The design of a trailer suspension has a significant impact on the overall stability and comfort during towing. Here’s a detailed explanation:

- Stability:

- 1. Weight Distribution: A well-designed suspension system ensures proper weight distribution across the trailer’s axles. It helps distribute the load evenly, preventing excessive weight on one axle and reducing the risk of overloading. Proper weight distribution enhances stability by maintaining the trailer’s balance and reducing the likelihood of swaying or fishtailing.

- 2. Center of Gravity: The suspension design plays a crucial role in managing the trailer’s center of gravity. A lower center of gravity improves stability by reducing the trailer’s tendency to tip or sway. Suspension systems with lower mounting points or those that incorporate features like torsion axles or independent suspension help lower the center of gravity and enhance overall stability.

- 3. Suspension Geometry: The geometry of the suspension system impacts stability by influencing factors such as wheel alignment, tracking, and roll resistance. A well-designed suspension geometry ensures that the wheels track properly, minimizing sideways movement and improving stability during turns or lane changes.

- 4. Damping Capability: The suspension design affects the damping capability, which refers to the system’s ability to absorb and dissipate shocks. Effective shock absorption reduces the transfer of vertical forces to the trailer, minimizing bouncing, oscillation, and excessive vertical movement. This helps maintain stability by preventing the trailer from becoming unsettled on uneven roads or encountering destabilizing forces.

- Comfort:

- 1. Shock Absorption: A well-designed suspension system effectively absorbs shocks and vibrations caused by road irregularities, bumps, or potholes. It utilizes components such as springs and shock absorbers to cushion the trailer, providing a smoother and more comfortable ride. Effective shock absorption reduces the jolts and vibrations felt inside the towing vehicle and minimizes the transfer of these forces to the cargo being transported.

- 2. Ride Quality: The suspension design influences the overall ride quality of the trailer. A suspension system that balances load support and shock absorption provides a more comfortable towing experience. It reduces excessive bouncing, pitching, or swaying, enhancing comfort for both the driver and passengers in the towing vehicle.

- 3. Noise and Vibration: A well-designed suspension system helps minimize noise and vibration during towing. It reduces the transmission of road-induced vibrations and impacts to the trailer’s frame and components. This results in a quieter and smoother ride, enhancing overall comfort and reducing driver fatigue.

- 4. Trailer Sway: The design of the suspension system can impact the trailer’s susceptibility to sway. Suspension systems that incorporate features like sway control mechanisms, independent suspension, or torsion axles offer improved resistance against trailer sway, enhancing stability and comfort during towing.

The design of the trailer suspension directly affects the stability of the trailer during towing:

The design of the trailer suspension also impacts the comfort experienced during towing:

In summary, the design of a trailer suspension significantly influences the overall stability and comfort during towing. A well-designed suspension system ensures proper weight distribution, manages the center of gravity, optimizes suspension geometry, and provides effective shock absorption. It enhances stability by reducing swaying, improving tracking, and minimizing vertical movement. Additionally, it improves comfort by absorbing shocks, reducing noise and vibration, and minimizing trailer sway. Choosing a suitable suspension design that meets the specific towing requirements is essential for achieving a stable and comfortable towing experience.